Sphere wrote on Sat Feb 21, 2009 7:55 pm:

Actually, I would have thought you would have better luck with the 3-cylinder. It seems to work pretty well for the Daihatsu engines? From what smart people have told me, a turbo on a single cylinder is useless, because there is too much time between the turbo spinning up and actually pushing air in the cylinder.

I think Sphere's comments are possibly on the right track:

According to Hugh MacInnes in his book

Turbochargers, a small engine usually requires a plenum (airbox) at the intake because the airflow slows between intake strokes. Here's a quote from Hugh's book, in which he is discussing a two cylinder engine compared to a four cylinder:

Air between the compressor discharge and the intake ports is stagnant half the time. During this time, it's possible for the compressor to go into surge.

When the intake valve opens at high rpm, the instantaneous engine demand can exceed the flow of the turbocharger.Intake manifold pressure will drop off even though the average flow is far below the capacity of the compressor.

The author he is discussing gasoline engines, but I expect a similar problem could show up on the slower revving diesels, perhaps to a lesser extent , and it would occur with superchargers as well as turbos. Paraphrasing the quote, what he's saying is there is still positive pressaure in the intake manifold but the air stops flowing because the intake valves are all closed. When an intake valve then opens, the air rushes so quickly into the cylinder that the intake manifold pressure drops off rapidly, adversely affecting the compressor. The plenum provides additional air capacity to minimize this problem. I suspect a single cylinder engine would make the problem worse. I guess only a sensitive recording pressure indicator would confirm this.

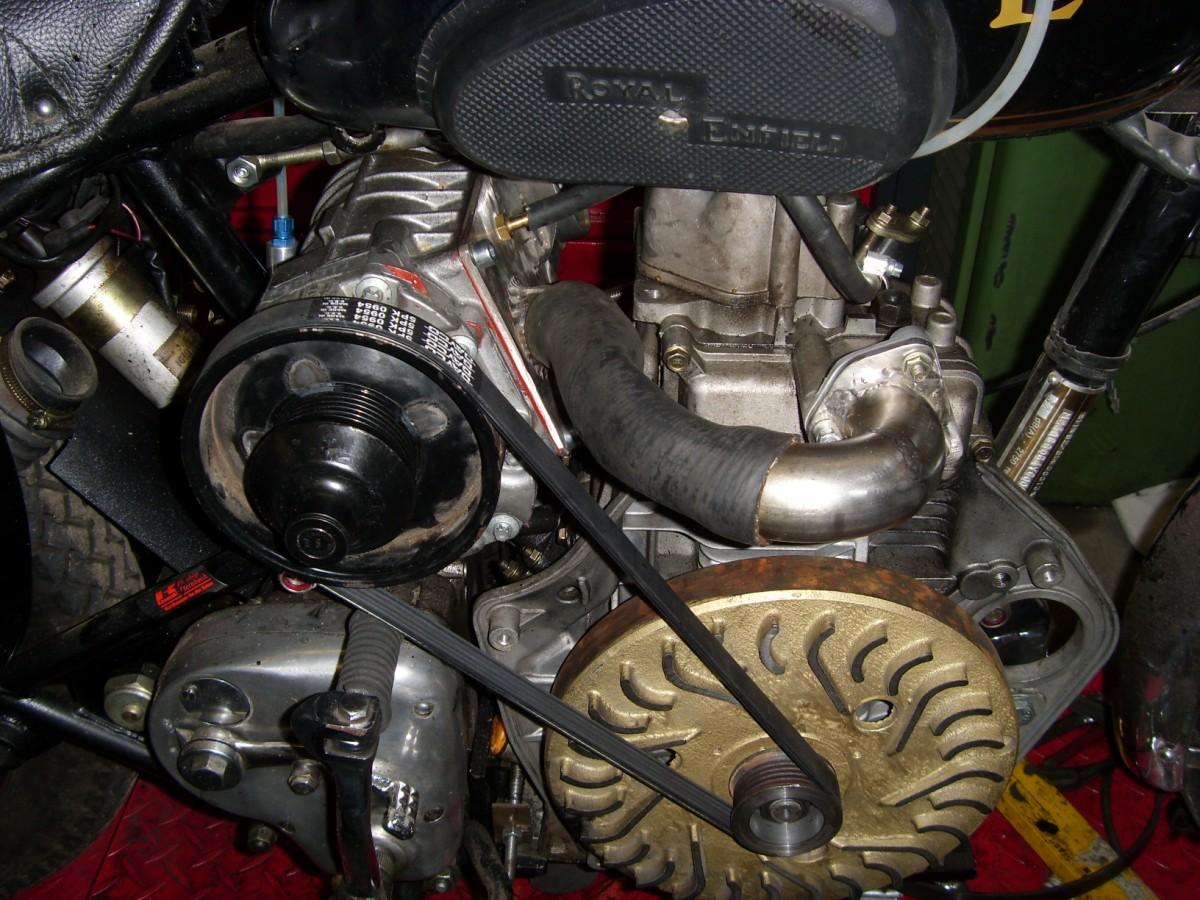

With respect to the efficiency of the supercharger, the engine first has to produce additional power to make up for the mechanical losses of the supercharger, and then make even more horsepower to realize any performance improvement. My instinct tells me there might be some performance improvement, but this would be offset by high fuel consumption. With no mechanical losses a turbo is definitely the way to go. I'd go for a small turbo that spins up quickly, coming in at low rpm, with a wastegate, and a plenum integrated into the inake manifold.

Hugh says you can successfully turbocharge any engine.

Back to the drawing board