Punsun mounts?

Moderators: Dan J, Diesel Dave, Crazymanneil, Stuart

-

roverthetop

- I luv the smell of Diesel...

- Posts: 94

- Joined: Thu May 17, 2007 3:37 am

- Location: portland, oregon, us

Punsun mounts?

1969 HD sporty, punsun, cvt to refresh minds...

pulled the engine to remount using something different. wondering thoughts on the following:

1" "plate" rubber underneath the entire lump, bolted through the frame.

and/ or

refabricate the original mounting "feet" (which are L shaped) to extend beyond the case

and/ or

leaf spring style bushing (bushes) integrated somehow

and/ or

refabricate mounting "feet" (L shaped) with instead of bolt holes upward, bore a large hole horizontally, rubber filled, with centerline through bolts?

any thoughts?

i was 1 day away from a test ride when fiddler had the mishap.

pulled the engine to remount using something different. wondering thoughts on the following:

1" "plate" rubber underneath the entire lump, bolted through the frame.

and/ or

refabricate the original mounting "feet" (which are L shaped) to extend beyond the case

and/ or

leaf spring style bushing (bushes) integrated somehow

and/ or

refabricate mounting "feet" (L shaped) with instead of bolt holes upward, bore a large hole horizontally, rubber filled, with centerline through bolts?

any thoughts?

i was 1 day away from a test ride when fiddler had the mishap.

dnepr lombardini 854cc convert

kwaker punsun vtwin convert (SVO as well)

harley sporty (cvt and SVO) done

harley softail (SVO) 6 spd in the works

kwaker punsun vtwin convert (SVO as well)

harley sporty (cvt and SVO) done

harley softail (SVO) 6 spd in the works

-

pietenpol2002

- I luv the smell of Diesel...

- Posts: 778

- Joined: Wed Dec 05, 2007 6:56 pm

- Location: Goshen, IN USA

First, you have to promise not to laugh. For many years the Pietenpol aircraft has used ash "engine bearers" to isolate the engine vibrations from the more fragile airframe that would otherwise be dismantled by the shake rattle and roll of certain engines. The use of ash has certainly withstood the test of time in that some Piets built in the 1930's using ash are still flying today. There is even one example that has bravely endured the pounding of a 4 cylinder Mercedes diesel. Wood is the ideal material for such an application in that it provides greater stability than certain rubber mounts and yet is relatively unphased by the engine vibrations. I also have a number of laminated ash landing gear that I built, still being horribly abused by those unfortunate souls who repeatedly and simultaneously run out of airspeed, altitude and ideas. And finally, it's light, cheap and very Fred-Flintstone-Like.

Below is an example of the 244 pound Ford Model A aircraft engine nestled onto the ash (sans cowl). The Ford-on-ash Piet is still being built in considerable numbers today after nearly 80 years.

http://tinyurl.com/4h7wg5

Cheers,

Ron

Below is an example of the 244 pound Ford Model A aircraft engine nestled onto the ash (sans cowl). The Ford-on-ash Piet is still being built in considerable numbers today after nearly 80 years.

http://tinyurl.com/4h7wg5

Cheers,

Ron

-

roverthetop

- I luv the smell of Diesel...

- Posts: 94

- Joined: Thu May 17, 2007 3:37 am

- Location: portland, oregon, us

ron,

would i want front and rear mounts, or an entire block? thickness? a carved tray for it to sit in? i'm a metal man, not a woodworker. any suggestions beyond what you've mentioned?

thanks!

b

would i want front and rear mounts, or an entire block? thickness? a carved tray for it to sit in? i'm a metal man, not a woodworker. any suggestions beyond what you've mentioned?

thanks!

b

dnepr lombardini 854cc convert

kwaker punsun vtwin convert (SVO as well)

harley sporty (cvt and SVO) done

harley softail (SVO) 6 spd in the works

kwaker punsun vtwin convert (SVO as well)

harley sporty (cvt and SVO) done

harley softail (SVO) 6 spd in the works

Brett,

1" rubber plate seems a good place to start. What method were you thinking of using to allow the bolts to stay torqued up? Some sort of metal sleeve through the rubber? Only concern and Iam no expert on the subject is what will holes and bolts do to the frame tubing strength? May not matter a bit but might compromise its integrity somewhat.

I like the idea of rubber inserts in the mounting blocks also, if Im picturing it in my head correctly your suggesting something similar to the way rubber mounted handlebars work but laid flat. Tried and trusted.

Ron,

I'll be steering clear of the wooden block approach. Decent timber is mighty costly over here and it would be just my luck to have one fail as it had a knott in it

Having said that, it wouldnt surprise me at all to see more and more natural materials utilised in manufacturing, replacing synthetics where it is appropriate, so not as crazy as it sounds.

1" rubber plate seems a good place to start. What method were you thinking of using to allow the bolts to stay torqued up? Some sort of metal sleeve through the rubber? Only concern and Iam no expert on the subject is what will holes and bolts do to the frame tubing strength? May not matter a bit but might compromise its integrity somewhat.

I like the idea of rubber inserts in the mounting blocks also, if Im picturing it in my head correctly your suggesting something similar to the way rubber mounted handlebars work but laid flat. Tried and trusted.

Ron,

I'll be steering clear of the wooden block approach. Decent timber is mighty costly over here and it would be just my luck to have one fail as it had a knott in it

Having said that, it wouldnt surprise me at all to see more and more natural materials utilised in manufacturing, replacing synthetics where it is appropriate, so not as crazy as it sounds.

-

roverthetop

- I luv the smell of Diesel...

- Posts: 94

- Joined: Thu May 17, 2007 3:37 am

- Location: portland, oregon, us

i was thinking a few things...

i think i want more crossmembers- as of now i have the 2 crossways (left to right) and i think i'll do 2 lengthwise as well, then my 1" rubber underneath the entire engine, supporting the whole case. i was then thinking bolts from underneath- frame, rubber, feet. lock (split) washers, locknuts, and loctite after cinching.

instead of rubber plate under just the feet. more airflow, but less vibration dampening is my thought.

a possible client just emailed this:

http://www.novibes.com/vibration/produc ... /index.asp

interesting. could use those top and bottom. i may ring them next week.

good thoughts, gents! i still think i'll end up blowing one up (turbo still in mind) but perhaps a bit longer than i thought...

b

i think i want more crossmembers- as of now i have the 2 crossways (left to right) and i think i'll do 2 lengthwise as well, then my 1" rubber underneath the entire engine, supporting the whole case. i was then thinking bolts from underneath- frame, rubber, feet. lock (split) washers, locknuts, and loctite after cinching.

instead of rubber plate under just the feet. more airflow, but less vibration dampening is my thought.

a possible client just emailed this:

http://www.novibes.com/vibration/produc ... /index.asp

interesting. could use those top and bottom. i may ring them next week.

good thoughts, gents! i still think i'll end up blowing one up (turbo still in mind) but perhaps a bit longer than i thought...

b

dnepr lombardini 854cc convert

kwaker punsun vtwin convert (SVO as well)

harley sporty (cvt and SVO) done

harley softail (SVO) 6 spd in the works

kwaker punsun vtwin convert (SVO as well)

harley sporty (cvt and SVO) done

harley softail (SVO) 6 spd in the works

-

pietenpol2002

- I luv the smell of Diesel...

- Posts: 778

- Joined: Wed Dec 05, 2007 6:56 pm

- Location: Goshen, IN USA

I can't quite envision your particular mount, however my Yanclone has feet that lend themselves well to simply bolting to 2 wooden crossmembers. A crossmember would better isolate the vibrations than simply bolting individual wood blocks between the engine and frame member where the vibrations can still be tranferred trough the bolt.

If any curvature was required you would need to resort to either steam bending or laminations. Neither is particularly difficult, but likely beyond the scope of this project. A 2X2 member of any good hardwood would be more than adequate. Unlike Fiddlers circumstances, high quality timber is readily available here, and with any defects graded out. I mentioned ash because of the weight concerns related to aircraft construction. For a bike one could use any number of species such as hiclory, oak, locust etc. I have in excess of 30,000 board feet out in the barns, so if you wanted to play around with the idea just PM me and I can send some your way.

In aircraft construction you have to resort to pretty exotic materials to surpass wood, assuming your design has capitalized on woods superior qualities. Steel and aluminum don't compare to Stitka Spruce. Furthermore, diesel makes a nice preservative for wood.

But ultimately, a good Lord type mount as depicted in your last post would do the job quite nicely.

Cheers,

Ron

If any curvature was required you would need to resort to either steam bending or laminations. Neither is particularly difficult, but likely beyond the scope of this project. A 2X2 member of any good hardwood would be more than adequate. Unlike Fiddlers circumstances, high quality timber is readily available here, and with any defects graded out. I mentioned ash because of the weight concerns related to aircraft construction. For a bike one could use any number of species such as hiclory, oak, locust etc. I have in excess of 30,000 board feet out in the barns, so if you wanted to play around with the idea just PM me and I can send some your way.

In aircraft construction you have to resort to pretty exotic materials to surpass wood, assuming your design has capitalized on woods superior qualities. Steel and aluminum don't compare to Stitka Spruce. Furthermore, diesel makes a nice preservative for wood.

But ultimately, a good Lord type mount as depicted in your last post would do the job quite nicely.

Cheers,

Ron

-

smokyjoe

- I luv the smell of Diesel...

- Posts: 201

- Joined: Mon May 26, 2008 1:42 am

- Location: Western Taxachusetts (Massachusetts) USA

Hey Piet,

A bit off subject but..... You burst my bubble- I thought I had an "original" idea of a Mercedes diesel (or maybe a VW TDI) in a plane like a Piet for a long time, another one of my way-on-the-back-burner ideas! I guess I'll stick to a Diesel bike right now. Nice machine, is that yours? I love it!

I was thinking of mounting my engine and and CVT to a plate, then using urethane sway bar bushings (with tubes around the through bolts) to the bike's frame. The Suzuki has a rubber vibration dampener of sorts (more for torque loads but would maybe do the same thing for shaking about) in the rear sprocket. Could also use a spring loaded idler or teflon or nylon slider on the slack side.

My question is though, what would the constant thrashing of the chain do for chain wear? My engine was originally in one of those walk-behind vibratory rollers and the whole machine wore out to be unrepairable while the engine still goes strong, so maybe I'm worrying about a problem that doesn't exist, at least in my case. The bolt holes in the mounts are worn quite a bit though......

A bit off subject but..... You burst my bubble- I thought I had an "original" idea of a Mercedes diesel (or maybe a VW TDI) in a plane like a Piet for a long time, another one of my way-on-the-back-burner ideas! I guess I'll stick to a Diesel bike right now. Nice machine, is that yours? I love it!

I was thinking of mounting my engine and and CVT to a plate, then using urethane sway bar bushings (with tubes around the through bolts) to the bike's frame. The Suzuki has a rubber vibration dampener of sorts (more for torque loads but would maybe do the same thing for shaking about) in the rear sprocket. Could also use a spring loaded idler or teflon or nylon slider on the slack side.

My question is though, what would the constant thrashing of the chain do for chain wear? My engine was originally in one of those walk-behind vibratory rollers and the whole machine wore out to be unrepairable while the engine still goes strong, so maybe I'm worrying about a problem that doesn't exist, at least in my case. The bolt holes in the mounts are worn quite a bit though......

- Diesel Dave

- Site Admin

- Posts: 1016

- Joined: Sat Dec 02, 2006 1:21 am

- Location: Essex, UK

- Contact:

Rubber Mounts

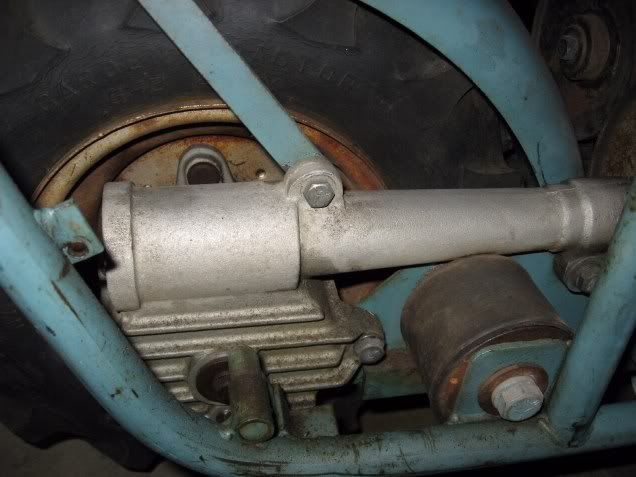

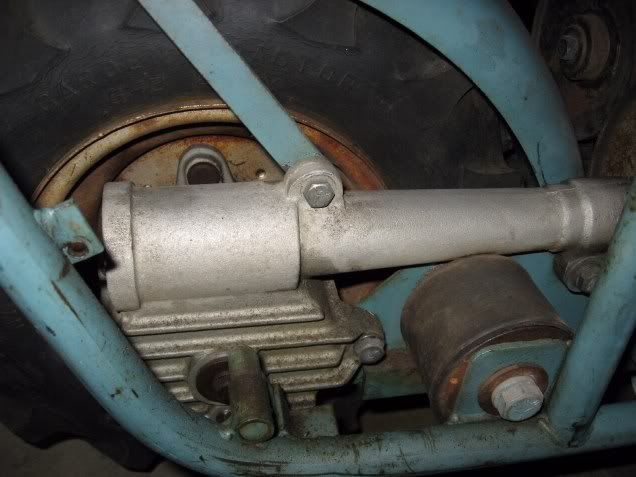

Thinking about rubber mounting engine I came across the follwing piccies and it clearly shows how the Tote Gote engine and transmission are isolated from the frame by rubber mounts. This is a Briggs side valve petrol motor - all cast iron so pretty weighty.

This shows a close up of the actual mounting - looks like some car engine mounts I have seen.

Looking at the overall picure you can see the front rubber mounting where it connects the entire subtray holding the engine and transmission.

Now some versions had a 2 speed gearbox as well as the Comet CVT - AND shaft drive too!

Nowt's new in this world!

Dave

This shows a close up of the actual mounting - looks like some car engine mounts I have seen.

Looking at the overall picure you can see the front rubber mounting where it connects the entire subtray holding the engine and transmission.

Now some versions had a 2 speed gearbox as well as the Comet CVT - AND shaft drive too!

Nowt's new in this world!

Dave

-

TnFan

- Been here a while now..

- Posts: 22

- Joined: Mon Sep 29, 2008 6:37 pm

- Location: Chattanooga Tennessee

- Contact:

Industrial Vibration Isolators

Industry commonly uses standard "Vibration Isolators" to mount motors in industrial settings. They should be relatively cheap and replaceable.

Here's only one link.

http://www.sdp-si.com/index.asp

Here's only one link.

http://www.sdp-si.com/index.asp