Ok so today the post delivered a few parts, mainly a new sprocket (25t Duplex) with just a pilot hole in the centre - 10 quid including delivery.

Also a small piece if 16mm mild steel - this is a very fortunate size..all will be revealed.

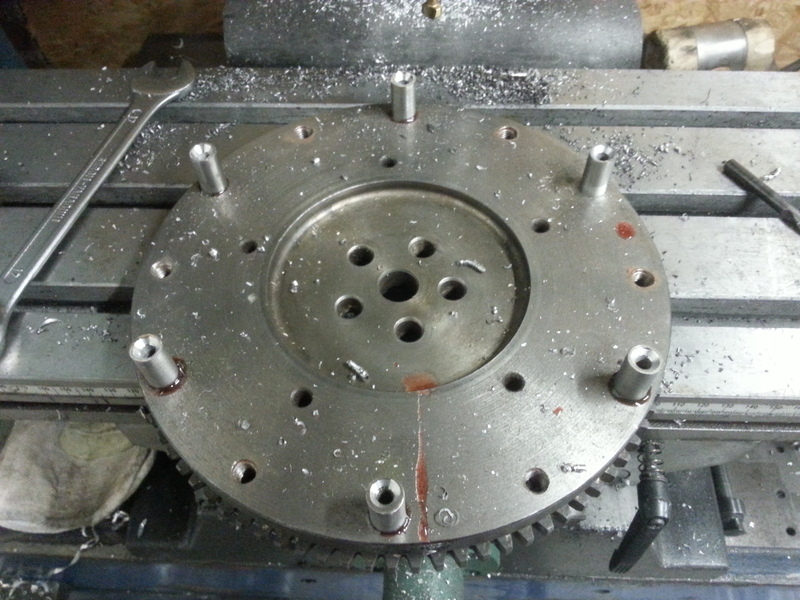

So we have a sprocket a flywheel and a bar of 16mm bright mild steel.

Luckily the hole in the flywheel and the pilot bore of the sprocket are both 16mm (sometimes things do work out!

So you can saw off a small piece and use it as an alignment spigot between the flywheel and the sprocket (doesn't have to be pretty just a hacksaw cut will do).

Also if you have the original taper fitting from the Aixam, it's spigot will fit into the sprocket hole so you can mark off the drill centres for the sprocket.

If you look carefully you can see the dots.

After drilling the sprocket (needs to be at least a pillar drill to get them vertical and they need to be as accurate as you can get them, clearance size for the M10x1.25 Hi Tensile bolts that will be used to secure the whole lot so thats 10.5mm)

So here is the sprocket and flywheel loosely installed as I only have a small bit of M10x1.25 studding available (still awaiting the bolts to arrive). The small piece of 16mm bar stock is in the centre and this aligns the sprocket with the flywheel (not the bolts)

So now you can see why cap heads are needed as std 13mm hex heads would clash with the primary chain.

More to follow