You also lost me, but thanks for giving it a shot.BertTrack wrote:Um from the top of my head. The speed of sound in air, is also the speed at which the pressure moves. Relative to temperature and air pressure. (keep that in mind)

Thinking in text here. (a loud)

So at 3000rpm you have 2000 low pressure dips, traveling at given sound speed through the tube, gives 33hz, the speed of sound is: (assume 343.2m/s) so your peaks/dips in pressure travel with 343,2/33 distance through the pipe, 10.4 meters between each peak umm? Doesn't look right.

But asume i'm right above, (which i doubt, it's been too long) the volume of air moved through the engine per second in relation to the diameter of the inlet will give the air speed. And you want the peak/dip to be double the frequency basically.

I lost myself... will think more about this. Maybe find my old papers from school on this subject.

Diesel Bike Diary

Moderators: Dan J, Diesel Dave, Crazymanneil, Stuart

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

# 8 - DonorCycle!

Date: 7-8-2015

Status: Obtaining parts

Look what arrived in the mail today!

https://youtu.be/KrS60n1PWaU

Smokes like hell (black) from the right-side cylinder and runs really hot while the other is cold and its carb is leaking fuel everywhere!

Sadly enough I need this engine to work for another 500 KM because I need to import it into the Netherlands on paper and get a plate for it... ...and that means riding it to the test center...

I'm guessing the right side is over-fueling like mad and the left is starving or just isn't running, thoughts?

Had a blast tough! ..and they said riding with a sidecar is hard...

..and they said riding with a sidecar is hard...

Date: 7-8-2015

Status: Obtaining parts

Look what arrived in the mail today!

https://youtu.be/KrS60n1PWaU

Smokes like hell (black) from the right-side cylinder and runs really hot while the other is cold and its carb is leaking fuel everywhere!

Sadly enough I need this engine to work for another 500 KM because I need to import it into the Netherlands on paper and get a plate for it... ...and that means riding it to the test center...

I'm guessing the right side is over-fueling like mad and the left is starving or just isn't running, thoughts?

Had a blast tough!

- coachgeo

- I luv the smell of Diesel...

- Posts: 2002

- Joined: Sun Feb 22, 2009 6:00 am

- Location: USA Ohio, Above Cincinnati, Close to Dayton

Re: Diesel Bike Diary

Congratulations. GREAT DONOR BIKE

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

Thanks, already had a go at treeing to fix it today.

Pulled the carbs apart, load of gunk inside, clean now.

Sparkplugs both sides sooty as all hell and the left side was still wet with fuel, checked for spark, plug on the left just didn't work. Getting a new one, hopefully it'll run properly tomorrow.

Luckily in a few weeks this thing won't have any spark plugs or carbs anymore!

For anyone interested its an Dnepr K750m built in 1969.

Pulled the carbs apart, load of gunk inside, clean now.

Sparkplugs both sides sooty as all hell and the left side was still wet with fuel, checked for spark, plug on the left just didn't work. Getting a new one, hopefully it'll run properly tomorrow.

Luckily in a few weeks this thing won't have any spark plugs or carbs anymore!

For anyone interested its an Dnepr K750m built in 1969.

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

# 8 - DonorCycle! #2

Date: 21-8-2015

Status: Building/Obtaining parts

Quite an event-full week has come and gone but the DonorCycle has passed inspections as an petrol powered bike and is now legal in the Netherlands!...

...So lets tear it apart!

Which took about 3 hours, taking it easy.

Ready for a diesel transplant I'd say, and then off to get inspected again!

Date: 21-8-2015

Status: Building/Obtaining parts

Quite an event-full week has come and gone but the DonorCycle has passed inspections as an petrol powered bike and is now legal in the Netherlands!...

...So lets tear it apart!

Which took about 3 hours, taking it easy.

Ready for a diesel transplant I'd say, and then off to get inspected again!

-

mark_in_manchester

- I luv the smell of Diesel...

- Posts: 320

- Joined: Mon Mar 19, 2007 9:04 am

- Location: Manchester, NW England, UK

Re: Diesel Bike Diary

Are you allowed to stretch it, or does the frame have to stay unchanged where you are?

You resurrected my gearbox thread, and now I see why. Well, I am around on here again, so if you have questions feel free to ask, and perhaps wake me with a PM which will cause something to ping into my regular email inbox.

cheers

Mark

You resurrected my gearbox thread, and now I see why. Well, I am around on here again, so if you have questions feel free to ask, and perhaps wake me with a PM which will cause something to ping into my regular email inbox.

cheers

Mark

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

Frame has to stay the same but I can stretch the wheel-base by 50mm. I'm moving the entire transmission and engine back/lower and putting an universal joint where the hardy disk used to be.mark_in_manchester wrote:Are you allowed to stretch it, or does the frame have to stay unchanged where you are?

Yeah I did, but I manged on my own. I've gotten an 20/26 as a third gear, a 23/23 fourth and a 10/35 Final Drive.mark_in_manchester wrote: You resurrected my gearbox thread, and now I see why. Well, I am around on here again, so if you have questions feel free to ask, and perhaps wake me with a PM which will cause something to ping into my regular email inbox.

cheers

Mark

They should all fit, but if you know any problems I might encounter please tell me about them.

Thanks for the offer tough, I might take you up on it. (Most likely when I run to trouble).

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

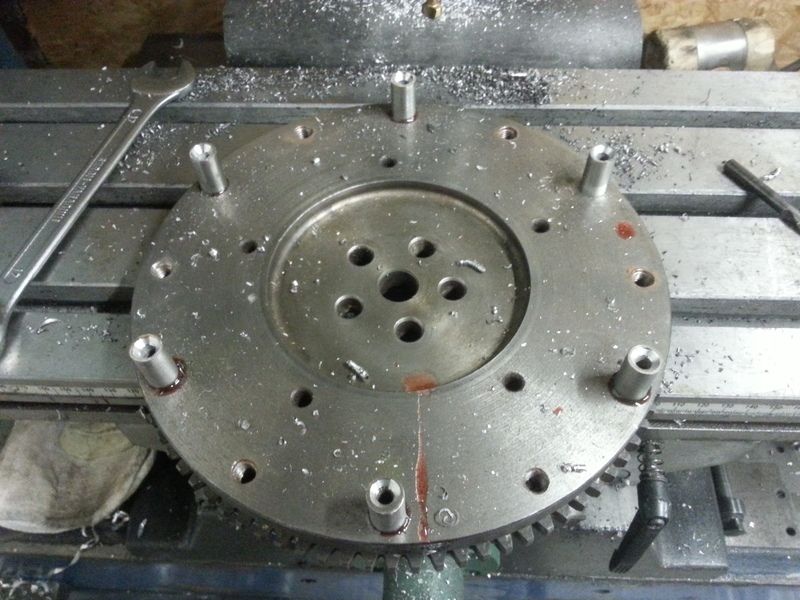

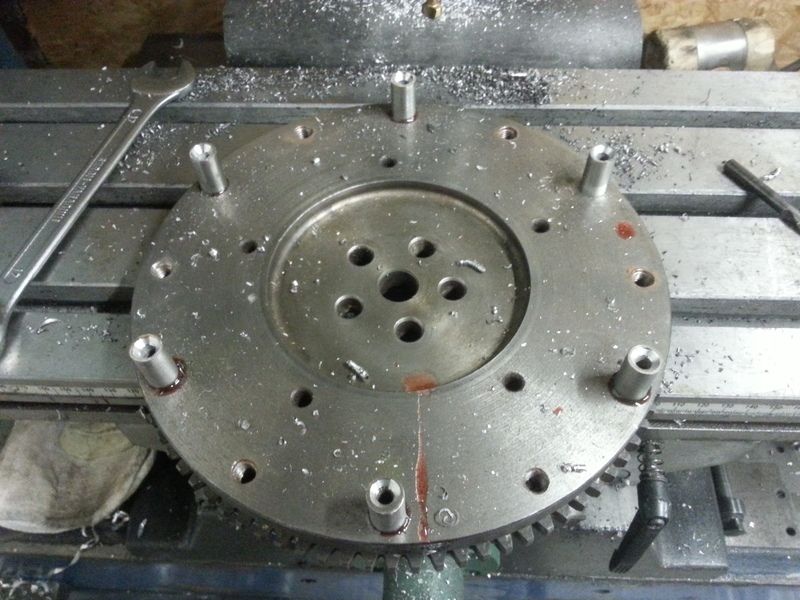

# 9 - The Build.

Date: 5-10-2015

Status: Building

As the title suggest, the build is finally underway!...

...And I've got a minor technical miracle to show off.

Behold!...

A kubota flywheel modified to fit a Dnepr K750 clutch pack!

A project which sounds simple... ...but was more trouble than I ever imagined.

For starters, the pegs that hold the clutch together on a Dnepr have an alignment that made me think that some guy with a hand drill just free handed them in...

So, forget just having evenly spaced out pegs, because those wont fit the center metal clutch plate, that means it will only ever go on in ONE way.

Nevertheless, it has been made...

On to the springs then! Shame about the balancing holes on the back of Kubota Flywheel tough!

The stock spring holes whould end up merging with the balancing holes on the backside of the flywheel.

So to solve that problem we used 2 kinds of different sized springs and spaced them out in an 3 on the inside and 3 on the outside pattern.

Added bonus; much, MUCH stiffer springs...

So now just make an clutch alignment tool, because why order something when you can just create it in 10 minutes...

...Aaaand now the last clutchplate is hitting the bolts which are holding on the flywheel, couldn't even assemble the clutch.

What now!? Why counter sink the bolts of course!... ...Just gotta make those M10 holes in the crankshaft to accept M12...

Ain't it pretty?

And now the result... ...technical porn!

Next on the list: Making an adapter plate!

Meanwhile I got some parts!

All the gaskets and seals I'll need,

2 Clutch plates of a newer design which didn't fit,

A tachometer,

20/26 third gear,

23/23 fourth,

and a 10/35 Final Drive.

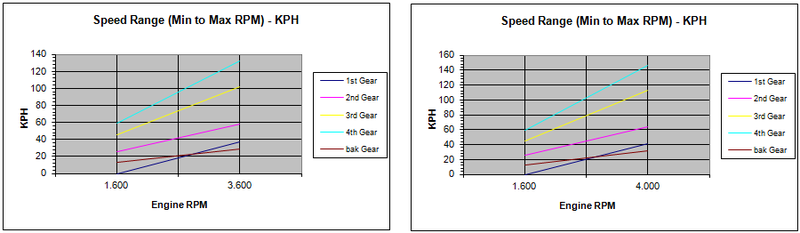

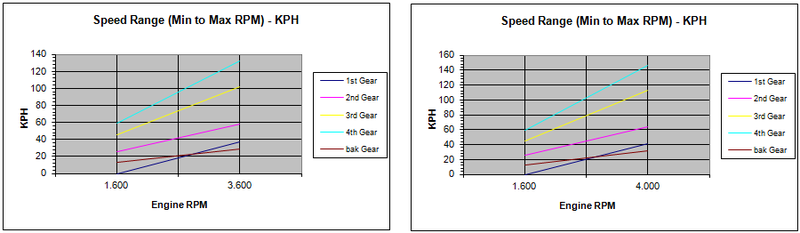

The gearing will mean that my shifting speeds look like this;

On a side note, who said you can't fit an motorcycle into the back of an family car?...

Date: 5-10-2015

Status: Building

As the title suggest, the build is finally underway!...

...And I've got a minor technical miracle to show off.

Behold!...

A kubota flywheel modified to fit a Dnepr K750 clutch pack!

A project which sounds simple... ...but was more trouble than I ever imagined.

For starters, the pegs that hold the clutch together on a Dnepr have an alignment that made me think that some guy with a hand drill just free handed them in...

So, forget just having evenly spaced out pegs, because those wont fit the center metal clutch plate, that means it will only ever go on in ONE way.

Nevertheless, it has been made...

On to the springs then! Shame about the balancing holes on the back of Kubota Flywheel tough!

The stock spring holes whould end up merging with the balancing holes on the backside of the flywheel.

So to solve that problem we used 2 kinds of different sized springs and spaced them out in an 3 on the inside and 3 on the outside pattern.

Added bonus; much, MUCH stiffer springs...

So now just make an clutch alignment tool, because why order something when you can just create it in 10 minutes...

...Aaaand now the last clutchplate is hitting the bolts which are holding on the flywheel, couldn't even assemble the clutch.

What now!? Why counter sink the bolts of course!... ...Just gotta make those M10 holes in the crankshaft to accept M12...

Ain't it pretty?

And now the result... ...technical porn!

Next on the list: Making an adapter plate!

Meanwhile I got some parts!

All the gaskets and seals I'll need,

2 Clutch plates of a newer design which didn't fit,

A tachometer,

20/26 third gear,

23/23 fourth,

and a 10/35 Final Drive.

The gearing will mean that my shifting speeds look like this;

On a side note, who said you can't fit an motorcycle into the back of an family car?...

-

mark_in_manchester

- I luv the smell of Diesel...

- Posts: 320

- Joined: Mon Mar 19, 2007 9:04 am

- Location: Manchester, NW England, UK

Re: Diesel Bike Diary

That's interesting - Ural clutches (at least from about 1970 on - don't know about earlier) use 2 friction disks, and (you provoked me to mild panic!) fit 1970s Dnepr shaft splines. So I guess K750 splines are different. It will be interesting to see if your high-ratio 3rd and 4th fit the K750 gearbox internals - if not you can substitute a later MT9 or MT11 box, but you might need to check that its overall dimensions are not slightly longer than what you have - I _think_ the 4 mounting holes will be in the same place.

I like your clutch tool. My milling machine (ahem - marriage of massive old pillar drill and wonky 3-axis table) would have made hours of that job. And I have no rotary table!

I like your clutch tool. My milling machine (ahem - marriage of massive old pillar drill and wonky 3-axis table) would have made hours of that job. And I have no rotary table!

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

The splines were fine. The friction disks were too thick. Advertised thickness was 4,5mm but in reality they were about 8mm...

The guy whom I got the gears from pulled them out of his own k750. So they should fit.

The guy whom I got the gears from pulled them out of his own k750. So they should fit.

-

mark_in_manchester

- I luv the smell of Diesel...

- Posts: 320

- Joined: Mon Mar 19, 2007 9:04 am

- Location: Manchester, NW England, UK

Re: Diesel Bike Diary

I guess your clutch can be as thick as you want to make the length of those pins on which the plain plates ride? But OK, I guess you are fighting for length if you are not allowed to stretch the frame. A 'thinner' approach (but which would throw away your excellent work on the Kubota flywheel) might be to use the Ukrainian flywheel, having machined the boss off the back of it; it's lighter, but works fine on my Daihatsu (easy tickover even at -5 deg C). The top plain plate can be supplied with a toothed rim for a starter - but I kick mine, which again works fine. There again I guess there might be not much in it from an overall length point of view.

Don't envy you fighting for every mm. I'm about to stretch another 20mm to take a Dnepr reverse gearbox. If you must leave the frame alone...may you modify the swing arm for your 50mm extra wheelbase?

Oh - edit to add I made my adaptor plates (two of them, spaced on 10mm HT bolts with aluminium spacers) out of 10mm steel plate. I regret it, a little - it's over the top, compared to the strength of the gearbox case itself. I think 10mm ali would have been fine if I could have found some scrap, or perhaps even 3 or 4mm steel with a wrapper rolled around the clutch (mine is open) and welded in with some stiffeners. What do you plan?

Don't envy you fighting for every mm. I'm about to stretch another 20mm to take a Dnepr reverse gearbox. If you must leave the frame alone...may you modify the swing arm for your 50mm extra wheelbase?

Oh - edit to add I made my adaptor plates (two of them, spaced on 10mm HT bolts with aluminium spacers) out of 10mm steel plate. I regret it, a little - it's over the top, compared to the strength of the gearbox case itself. I think 10mm ali would have been fine if I could have found some scrap, or perhaps even 3 or 4mm steel with a wrapper rolled around the clutch (mine is open) and welded in with some stiffeners. What do you plan?

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

Yes, we could do that and I believe we have the space in the frame for it but we're using the Dnepr crankcase as an adapter so space is limited. Thing is, I'd much rather use the Kubota starter engine, way more reliable and designed to be used for this engine. Also, the Kubota engine is externally balanced by holes in the flywheel. That and the mounting pins on the Dnepr are anything but precisely made so we'd have to precisely remake the mounting pins all over, AGAIN.mark_in_manchester wrote:I guess your clutch can be as thick as you want to make the length of those pins on which the plain plates ride?

But OK, I guess you are fighting for length if you are not allowed to stretch the frame. A 'thinner' approach (but which would throw away your excellent work on the Kubota flywheel) might be to use the Ukrainian flywheel, having machined the boss off the back of it; it's lighter, but works fine on my Daihatsu (easy tickover even at -5 deg C). The top plain plate can be supplied with a toothed rim for a starter - but I kick mine, which again works fine. There again I guess there might be not much in it from an overall length point of view.

Yes, anything that's not the frame. Otherwise chain driven motorcycles would have problems with tensioning. We're actually allowed to change the frame/wheelbase but then you can't change out the engine. (Weird Dutch bureaucracy).mark_in_manchester wrote: Don't envy you fighting for every mm. I'm about to stretch another 20mm to take a Dnepr reverse gearbox. If you must leave the frame alone...may you modify the swing arm for your 50mm extra wheelbase?

Use the Dnepr crankcase, cut the flywheel side off and use that to bolt it onto the engine.mark_in_manchester wrote: Oh - edit to add I made my adaptor plates (two of them, spaced on 10mm HT bolts with aluminium spacers) out of 10mm steel plate. I regret it, a little - it's over the top, compared to the strength of the gearbox case itself. I think 10mm ali would have been fine if I could have found some scrap, or perhaps even 3 or 4mm steel with a wrapper rolled around the clutch (mine is open) and welded in with some stiffeners. What do you plan?

Re: Diesel Bike Diary

Hi tetronator, and diesel heads. Im working on adapting an Ural flywheel was wondering if you could check out my idea. https://www.dieselbikeforum.com/view ... =31&t=3162

Thx,

-Matt

Thx,

-Matt

Re: Diesel Bike Diary

I plan on making my adapter plate from a thick piece of aluminum. 2 inches thick (.05 meters). and one square foot area (.09 meters^2). Im looking at about $250 USD. What's your idea for an adapter plate?

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

MotoUral wrote:I plan on making my adapter plate from a thick piece of aluminum. 2 inches thick (.05 meters). and one square foot area (.09 meters^2). Im looking at about $250 USD. What's your idea for an adapter plate?

Tetronator wrote:Use the Dnepr crankcase, cut the flywheel side off and use that to bolt it onto the engine.mark_in_manchester wrote: Oh - edit to add I made my adaptor plates (two of them, spaced on 10mm HT bolts with aluminium spacers) out of 10mm steel plate. I regret it, a little - it's over the top, compared to the strength of the gearbox case itself. I think 10mm ali would have been fine if I could have found some scrap, or perhaps even 3 or 4mm steel with a wrapper rolled around the clutch (mine is open) and welded in with some stiffeners. What do you plan?(Work in progress tough.)

-

gearhead1951

- I luv the smell of Diesel...

- Posts: 129

- Joined: Fri Oct 12, 2012 9:04 am

- Location: scotland uk

Re: Diesel Bike Diary

find the shrink scale for casting alloy , make a wooden adaptor using that scale then ram up a mold , melt and pour !

For more info on how to do that go to http://www.alloyavenue.com and if you REALLY need help go to http://www.backyardmetalcasting.com !

Also check the "Maserati bike build at http://www.jockeyjournal.com/forum/ to see a casting that was made to adapt a fore and aft mounted engine to a chain drive (Harley) trans !!!

Good luck and have fun !

For more info on how to do that go to http://www.alloyavenue.com and if you REALLY need help go to http://www.backyardmetalcasting.com !

Also check the "Maserati bike build at http://www.jockeyjournal.com/forum/ to see a casting that was made to adapt a fore and aft mounted engine to a chain drive (Harley) trans !!!

Good luck and have fun !

-

gilburton

- I luv the smell of Diesel...

- Posts: 761

- Joined: Sat Apr 21, 2007 11:35 am

- Location: UK northants

Re: Diesel Bike Diary

Different engine but this guy used half a wheel??MotoUral wrote:I plan on making my adapter plate from a thick piece of aluminum. 2 inches thick (.05 meters). and one square foot area (.09 meters^2). Im looking at about $250 USD. What's your idea for an adapter plate?

http://www.4btswaps.com/forum/showthrea ... Robin-DY35

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

# 10 - The Build.

Date: 21-11-2015

Status: Building

Project had a temporary hold up due to various things but some progress has been made.

A picture is worth a thousand words, I've got six.

Date: 21-11-2015

Status: Building

Project had a temporary hold up due to various things but some progress has been made.

A picture is worth a thousand words, I've got six.

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

# 11 - The Build.

Date: 25-2-2016

Status: Building

Another 2 months have passed and the plan of reusing part of the Dnepr engine casing as an adapter didn't work, sadly enough. So one had to be created from scratch.

New plan; Aligning gearbox/clutchpack with engine crankshaft/flywheel by machining the 4 "posts" to make it all fit together properly before welding it all up.

The general idea.

Checking runout; all within 0,1 mm.

https://youtu.be/4snJvHV9miA

...And welding it up, you can still see the spacer in between.

Coverplates.

Would be a shame if the starter didn't fit.

Result!

So... Something about choppers, am I rite?

Now lets see if my measurements and 3D modelling was right about fitment!...

On, the, money.

All-tough, as feared the valve cover is fouling the upper frame and the fuel-tank bracket plus there's a bit of an clearance issue with the water-pump pulley.

That's all for now but its actually starting to look like something!

Date: 25-2-2016

Status: Building

Another 2 months have passed and the plan of reusing part of the Dnepr engine casing as an adapter didn't work, sadly enough. So one had to be created from scratch.

New plan; Aligning gearbox/clutchpack with engine crankshaft/flywheel by machining the 4 "posts" to make it all fit together properly before welding it all up.

The general idea.

Checking runout; all within 0,1 mm.

https://youtu.be/4snJvHV9miA

...And welding it up, you can still see the spacer in between.

Coverplates.

Would be a shame if the starter didn't fit.

Result!

So... Something about choppers, am I rite?

Now lets see if my measurements and 3D modelling was right about fitment!...

On, the, money.

All-tough, as feared the valve cover is fouling the upper frame and the fuel-tank bracket plus there's a bit of an clearance issue with the water-pump pulley.

That's all for now but its actually starting to look like something!

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

# 12 - The Build.

Date: 19-6-2016

Status: Building

Man, this endeavor is taking a while. But time is money and I do not have a lot of money, so, time it is.

Taking part in two motorcycle accidents doesn't help either.

Main frame and engine mounting bits are done!

But of course the belt now fouls the frame thus there was a need to get creative.

It's all so close now, hopefully more soon!

Date: 19-6-2016

Status: Building

Man, this endeavor is taking a while. But time is money and I do not have a lot of money, so, time it is.

Taking part in two motorcycle accidents doesn't help either.

Main frame and engine mounting bits are done!

But of course the belt now fouls the frame thus there was a need to get creative.

It's all so close now, hopefully more soon!

-

sbrumby

- I luv the smell of Diesel...

- Posts: 517

- Joined: Sun Dec 10, 2006 8:35 pm

- Location: STAFFORDSHIRE ENGLAND

Re: Diesel Bike Diary

You will probably find coged belts don't take to being bent backwards but they should last a while. As they don't cost a fortune replacement after a couple of years is no big deal.

Sam

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

Mouse warned me for this already.

The specifications for the belt indicate it should be able to handle this amount of bending.

If this is going to be an issue I can always replace the bearings with bigger ones.

And as you said, if they last long enough, it'll be fine.

The specifications for the belt indicate it should be able to handle this amount of bending.

If this is going to be an issue I can always replace the bearings with bigger ones.

And as you said, if they last long enough, it'll be fine.

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

The frame is cleared for now, but I might just do that.UAofE wrote:Mount the alt higher?

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

# 13 - The Build.

Date: 21-8-2016

Status: Building

Owning an diesel bike also means that there's a need for a vessel to contain said diesel on the vehicle... ...19 Liters of the stuff.

Behold!

With fuel return line!

As you have probably seen, there's some rust in the tank, I figured i'd remove it with some diluted Rustyco... Yeah, bad idea, don't do it. That needed re-welding.

'

'

And of course the brilliant Monza fuelcap, here's some pictures.

Now for anyone else wanting to do this, a word of warning. The Dnepr fuel tank is made from highcarbon steel which made it very hard to weld, it might just be easier to make a new fuel tank.

Date: 21-8-2016

Status: Building

Owning an diesel bike also means that there's a need for a vessel to contain said diesel on the vehicle... ...19 Liters of the stuff.

Behold!

With fuel return line!

As you have probably seen, there's some rust in the tank, I figured i'd remove it with some diluted Rustyco... Yeah, bad idea, don't do it. That needed re-welding.

'

'And of course the brilliant Monza fuelcap, here's some pictures.

Now for anyone else wanting to do this, a word of warning. The Dnepr fuel tank is made from highcarbon steel which made it very hard to weld, it might just be easier to make a new fuel tank.

- Diesel Dave

- Site Admin

- Posts: 1016

- Joined: Sat Dec 02, 2006 1:21 am

- Location: Essex, UK

- Contact:

Re: Diesel Bike Diary

Your welding is improving though!

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

Thanks, but... ...I wish I could weld that good, a friend of mine is helping me out on this one. (He wishes he hadn't tough, this is one tough cookie.)

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

# 14 - The Build.

Date: 13-11-2016

Status: Building

Well then, all-most 3 months have passed but this time, stuff got done! So much in-fact that I didn't even took the time to post it all.

So here comes the catch up!

One of the first things a friend of mine noticed when I got the Dnepr was the fact that the rear springs were set slightly forward, which is an absolute no-no for suspension as this will cause the opposite of progressive springs.

So that had to be fixed, and while I was at it I might as well get some actual proper springs for the thing.

Upon disassembly we also noticed that the swing-arm mounting method was also absolute rubbish. Another thing to be fixed!

Insert, proper bearings! Courtesy of an Yamaha XJ750.

With that fixed, onto the shocks! YSS Progressive shocks, mounted canted forwards for added progressiveness. Isn't it a thing of beauty?

Now an engine needs an exhaust, and wouldn't it be nice if it was tuned in such a way that the exhaust pulses will pull even more air out of the combustion chamber?

First off, flanges, stainless CNC-milled, flanges of-course...

https://youtu.be/GVtR3P48zCI

Perfect fit! Time for the tiniest exhaust bends ever!

Those were fun to make... Now an collector!

Put it all together...

Add some more bits in-between...

Close the gaps, and if you're wondering. Yes, the runners are of different length but, because of the design, the center exhaust pulses carry more momentum thus nullifieng the difference in length.

Now to add some length and direct the exhaust where I want it to go.

I guess I should add a muffler... But of-course an resonance muffler, non of those power-robbing baffles in here!

Now for the finishing touch! Cleaning up the oxidation off of the welds.

Exhausting, wasn't it? But we're not done yet!

More clearance issues to resolve...

And having had enough of searching for an suitable thermostat housing top, its a long-un!

Peek-a-bo.

Slightly cheating... ...And a bit more welding, seems an zinc-primer really helps with welding these tanks, somehow.

Oil-pan mods! I wanted an temperature sensor and properly located drain plug.

And I'll leave you with an slight preview on what to expect next time...

Date: 13-11-2016

Status: Building

Well then, all-most 3 months have passed but this time, stuff got done! So much in-fact that I didn't even took the time to post it all.

So here comes the catch up!

One of the first things a friend of mine noticed when I got the Dnepr was the fact that the rear springs were set slightly forward, which is an absolute no-no for suspension as this will cause the opposite of progressive springs.

So that had to be fixed, and while I was at it I might as well get some actual proper springs for the thing.

Upon disassembly we also noticed that the swing-arm mounting method was also absolute rubbish. Another thing to be fixed!

Insert, proper bearings! Courtesy of an Yamaha XJ750.

With that fixed, onto the shocks! YSS Progressive shocks, mounted canted forwards for added progressiveness. Isn't it a thing of beauty?

Now an engine needs an exhaust, and wouldn't it be nice if it was tuned in such a way that the exhaust pulses will pull even more air out of the combustion chamber?

First off, flanges, stainless CNC-milled, flanges of-course...

https://youtu.be/GVtR3P48zCI

Perfect fit! Time for the tiniest exhaust bends ever!

Those were fun to make... Now an collector!

Put it all together...

Add some more bits in-between...

Close the gaps, and if you're wondering. Yes, the runners are of different length but, because of the design, the center exhaust pulses carry more momentum thus nullifieng the difference in length.

Now to add some length and direct the exhaust where I want it to go.

I guess I should add a muffler... But of-course an resonance muffler, non of those power-robbing baffles in here!

Now for the finishing touch! Cleaning up the oxidation off of the welds.

Exhausting, wasn't it? But we're not done yet!

More clearance issues to resolve...

And having had enough of searching for an suitable thermostat housing top, its a long-un!

Peek-a-bo.

Slightly cheating... ...And a bit more welding, seems an zinc-primer really helps with welding these tanks, somehow.

Oil-pan mods! I wanted an temperature sensor and properly located drain plug.

And I'll leave you with an slight preview on what to expect next time...

- Diesel Dave

- Site Admin

- Posts: 1016

- Joined: Sat Dec 02, 2006 1:21 am

- Location: Essex, UK

- Contact:

Re: Diesel Bike Diary

I have to admit Alex - your making a reasonable effort of this build...

And your welding has come on leaps and bounds.

And there's only 6 months to go before the big knock.

Failing that 10 months to Hamm.

I might come on a petrol bike just to be controversial.

And your welding has come on leaps and bounds.

And there's only 6 months to go before the big knock.

Failing that 10 months to Hamm.

I might come on a petrol bike just to be controversial.

- Tetronator

- I luv the smell of Diesel...

- Posts: 502

- Joined: Mon Apr 07, 2014 11:50 am

- Location: Amsterdam

- Contact:

Re: Diesel Bike Diary

Either I'm doing it right, or I won't do it at all.Diesel Dave wrote:I have to admit Alex - your making a reasonable effort of this build...

I wish it was my welding! Said anonymous friend is the master of the arc here.Diesel Dave wrote: And your welding has come on leaps and bounds.

Go BIG or go home!... Big Knock that is!Diesel Dave wrote: And there's only 6 months to go before the big knock.

Failing that 10 months to Hamm.

HERESY!Diesel Dave wrote: I might come on a petrol bike just to be controversial.

I saw something come by on FB... ...The Black Douglass?...