A lovely day out was had at Tim's in Somerset on Friday. He, very kindly, taught me how to use a lathe and helped me sort out the pulleys and the rear sprocket. It was thoroughly entertaining! Thanks again Tim!

The pulley going into the lathe:

The initial layer removed from the inside of the pulley, mainly for weight savings:

Swapped around now, and removing the main part of the pulley, where the clutch basket will sit:

After a lot more turning:

Shiny shiny!:

Drilled the holes and wacked the back plate of the clutch basket inside:

And with the basket in place:

All I need is the correct size bolts and all will be done for that!

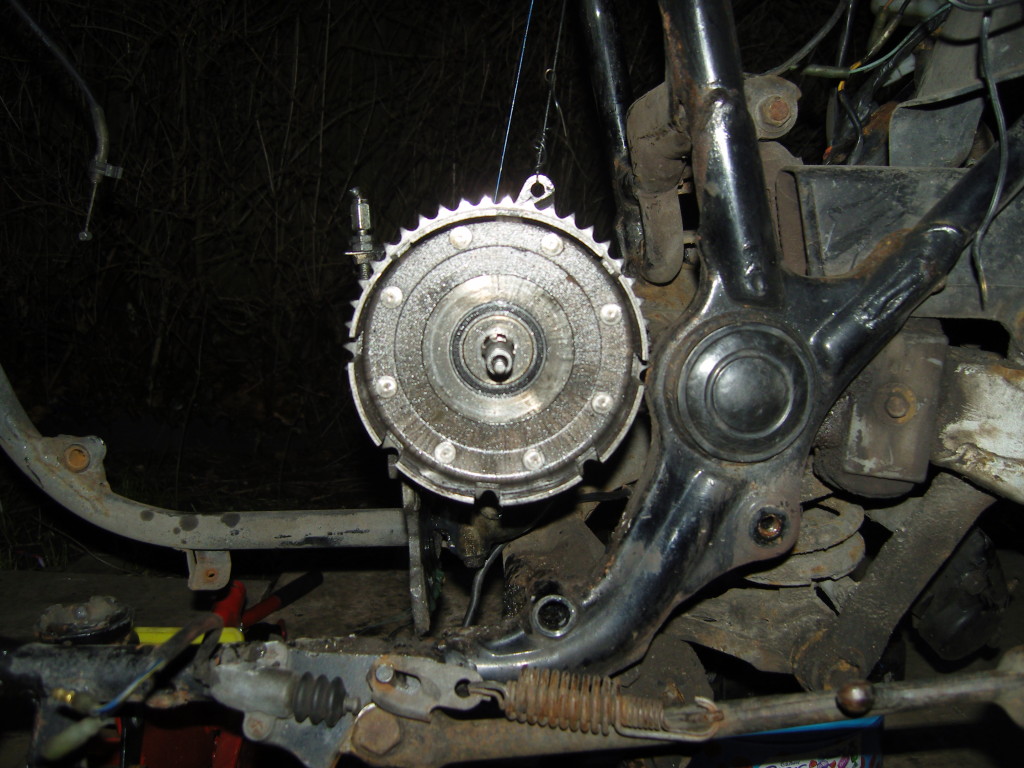

Now time for the sprocket, it needed to fit over a 12cm wide sprocket hub:

After lots of turning (The rim and the center boss) and we drill the holes and mount it to the hub center:

Lovely Jublies!

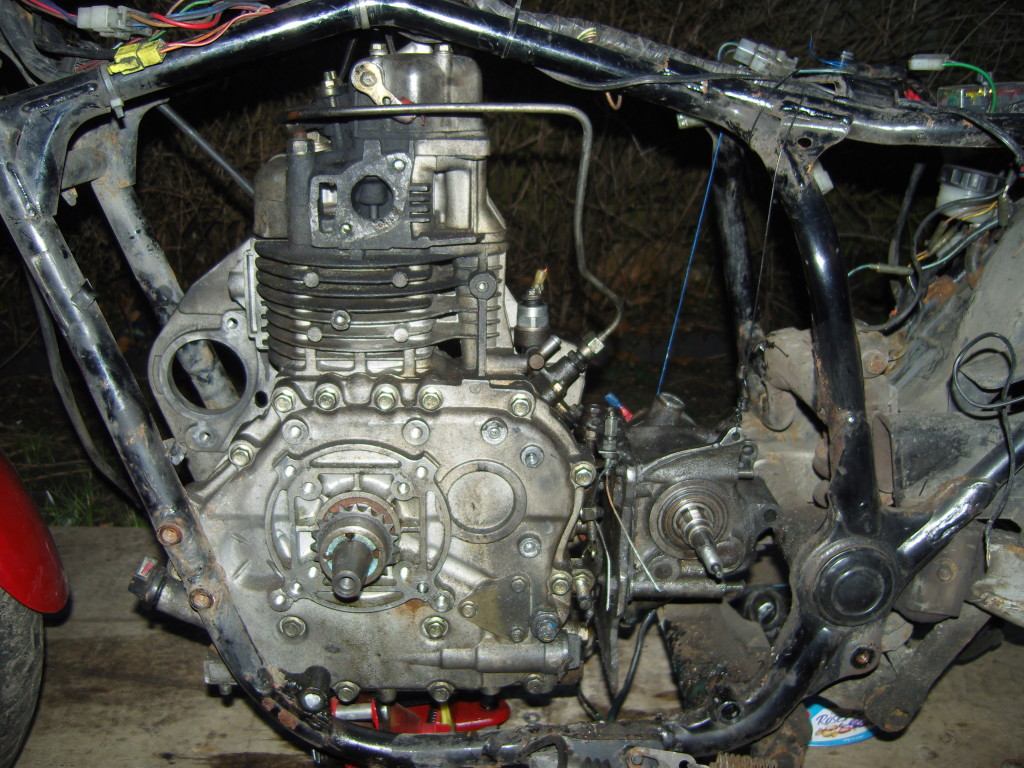

All sorted, and today I did some test fitting of the engine and the gearbox with the pulley on it, Turns out, the engine needs to go forward another 2 inches! Argh, teaches me to weld and not measure things, after some cutting and re-welding I had extended the engine mount a further 2 inches:

I was worried about clearance with the front wheel (it looks closer than it is), so I compressed the front forks using wratchet straps and checked throughout the steering movement! All ok!

A view from the other side with the pulley on top of the crank, this is as far forward as I can get the engine:

Some close ups of the individual welds, I ran out out of gas halfway through and had to switch to flux cored wire (thats a lot more work! Grr):

I ended up re-doing a lot of these as I didnt have the power up high enough and the weld was just sitting on top of the frame

My new toy

Slowly getting there.