I tougth of making this thread as a log for my dieselbike building experience from the ground up.

'What does this mean!?' I hear you ask! I really mean from the ground up, from idea to reality, this might span years or months depending on my luck and/or setbacks.

You could see this as a diary of sorts, I guess.

I will post when I hit a mile-stone and will also add that post into this first post with a date, number and project status for your viewing pleasure.

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 1 - Miles with Smiles

Date: 16-4-2014

Status: Idea - Research

I have been thinking about a diesel powered motorcycle since as long as I have been riding, about 4 years, the reason beeing the same as why I choose to ride motorcycles instead of driving a car, it's economical...

...AND REALLY FUN!!!

"But why the diesel? Its cheaper to run but heavy and lacks the power of a petrol engine!" I hear the nay-sayers scream!

Simple ; I, like, TORQUE. Especially on the lower RPM's... And the ability to run on anything from fryer grease to motor oil...

So with that in mind I went online and found out that there are like minded people out there, and I lurked around for a couple of years forming idea's on how I am going to accomplish this.

Eventually becoming a member of this forum.

So here's where I am now, head busting with idea's. But no means to make these idea's a reality.

I have come up with a list of goals I wish to achieve with the diesel bike & certain contenders to achieve that.

I will update this list when needed, please share your tougths on this!

Goals (If at all possible)

#1. Cruise Speed of 130 km/h (Legal highway limit here in the netherlands. Bonus points: With a sidecar)

#2. Max speed of 140 km/h (Overtaking possibilities)

#3. Reliability, Its going to be a workhorse if anything.

#4. Multi fuel, I'd like to be able to run it on just about anything that says oil or grease on it.

Engine Contenders (This one really depends on what I can get my hands on tough... But these are mostly available in the netherlands and also any spare parts.)

#1. Any small front wheeldrive car diesel engine with its gearbox & transaxle.

#2. Yanmar

#3. Hatz

#4. Kubota

#5. Lombardini/Kohler (Same engines I believe)

#6. Deutz (Too big but, size matters right?

#7. Lister(...Maybe?...)

Donor Bike Contenders

#1. Dnepr (Cheap & able to get tax free if old enough)

#2. Ural (Cheap & able to get tax free if old enough)

#3. BMW (Not likely, very expensive)

#4. Moto Guzzi (1000cc or more, stronger gearbox and better ratio's)

#5. Custom Frame (Not likely, very expensive)

#6. Honda Super Magna (A lot of space in that frame)

Gearbox Contender (If required, and no I do not like CVT's, trash dem gears!

#1. Dnepr

#2. Ural

#3. BMW (Not likely, very expensive)

#4. Moto Guzzi

#5. Small car gearbox + transaxle.

With these in mind I was thinking something along the line of a 2 or 3 cilinder tax free Dnepr/Ural diesel bike. Preferably with the least amount of frame modifications, considering I have no acces to any workshop and very little actual workshop experience my self. So all things considered, I'll probably have to drop or lower some of the goal's I have set, at least for my first build. But please tell me if you think otherwise, I'd like to learn from your experiences!

Dang, this took me a while to set up...

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 2 - The road to success is always under construction!

Date: 9-10-2014

Status: Further Research

Righto, Allmost 6 months have passed since my first message. But I haven't been sitting still! Been to the Hamm Rally and the automotoren treffen on Texel. Also looked at a few Dnepr's and Ural's and I'm sure enough that I will be using a Dnepr or Ural bike. As for the engine, because I need to have as little frame modification as possible, preferably none at all. I'm stuck to either the small one cilinders, (Hatz 1b40, Kubota Z482, Yanmar L100), or a V-twin Kipor which are neigh impossible to get with any kind of spare parts backing in the Netherlands...

...But there is hope for a more powerfull option!...

If I take a look at this bike ;

Which has an Hatz 1b40.

Look at the dimensions of said Hatz 1b40.

http://www.hatz-diesel.com/uploads/tx_h ... -22_02.pdf

It might just be possible to fit any of these kubota multicilinder engines in there... Thinking the sump will find it place between the lower frame bits. (Might need to shorten the sump if it all possible due to road clearance.)

Z602 15,8HP http://www.prinsmaasdijk.nl/motoren/2/k ... -Z602.html

D722 19,0HP http://www.prinsmaasdijk.nl/motoren/2/k ... -D722.html

I will also have too remove the waterpump, fan and alternator to make that fit. Repalcing the water pump with an electric one and attaching the alternator somehow somewhere else.

Added bonus of using a Kubota is that apearantly a BMW R80 Gearbox is mostly bolt-on.

Stated here; https://www.dieselbikeforum.com/view ... ota#p12706

Now does a bmw R80 gearbox just bolt in place of the Dnepr/Ural One? (Doubtfull.)

So, Unmodified Dnepr/Ural frame with a BMW r80 gearbox powered by a Kubota D722/Z602?

Research aside, still no place for me to work on the bike or metalworking tools to do so...

Anyway thats all for now that I can think of. Share your tougths please! You're all more experienced than I am afterall.

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 3 - Westenberg Special

Date: 12-11-2014

Status: Designing

Another month bites the dust. But a lot has been accomplished in that month. For I now have an actual idea on how I'm going to put this together!

Donor bike

A Dnepr K-750 or Ural M-72.

Preferably the Dnepr because the gearboxes in the Dneprs seem to be off a stronger build and I have found the ratio's & replacement gears online.

Why the Dnepr?:

-Lower noise regulations

-Tax Exemption if I do not stretch the wheelbase more than 60mm (Not planning on stretching) because I get to keep the original license plates.

-The wheels are all the same, thus interchangeable.

-Cheap parts.

-Cool looks

-Gearing changeable

-Cheap on purchase

-Sidecar

Gearbox & Clutch

I'm thinking of using the Dnepr gearbox and machining the diesel engine's flywheel to accept the Dnepr Clutch assembly. Keeping it all in its original position by lobbing the flywheel cover off of the Dnepr engine and using it to mate the diesel engine to the gearbox.

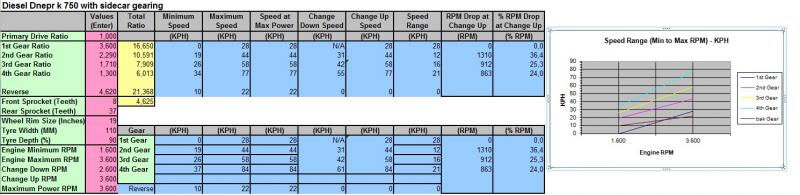

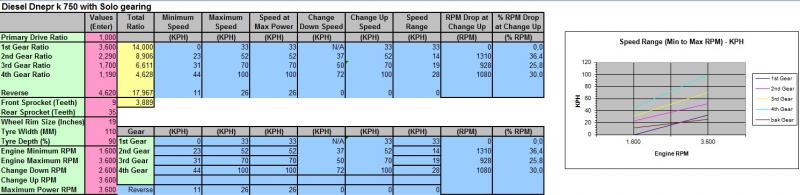

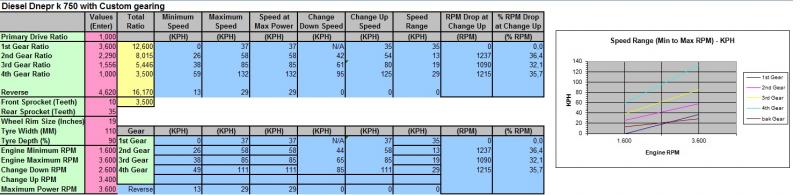

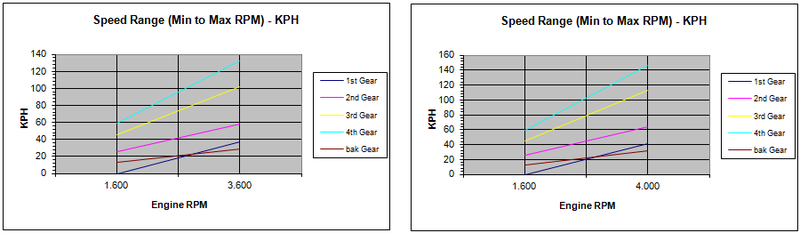

Using the Dnepr gearbox geared for Solo use it will need some ratio changes to make full use of the diesel powerband.

So I found this: http://www.dneprside.dk/dnepr_k750_gear_tabel.htm

Slight edit later, we get this:

As you can see above a top speed of 130km/h is obtainable using off the shelf gearing with an maximum RPM of 3600.

If you see anything wrong in the table above, please let me know...

Eitherway said gearing will require quite some power so on to the next point!

Engine

Getting that top speed of 130km/h means that any single cylinders engines are not adequate enough for the job. These machines, (...and me...

So the engine needs enough power & be able to fit into the Dnepr frame without stretching it...

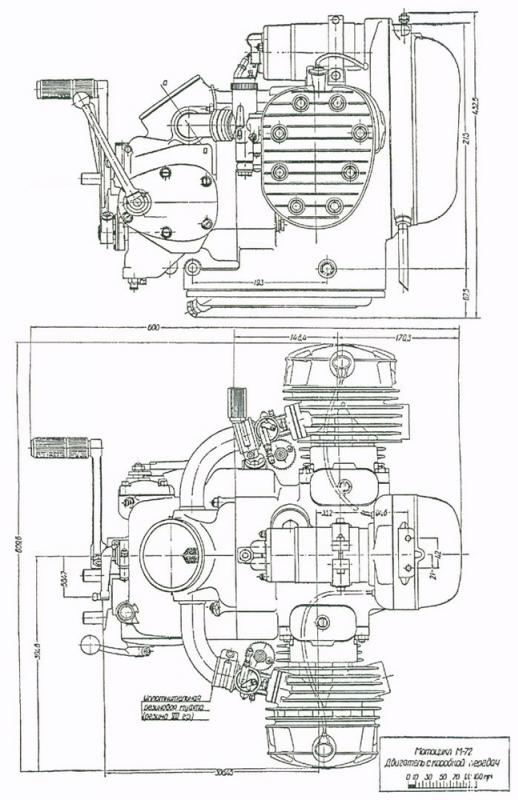

Dimensions of the original engine:

[/url]

[/url]Therefore I have selected these engines:

(Preferred) Kubota D722

http://www.prinsmaasdijk.nl/motoren/2/k ... -D722.html

Advantages:

-Parts readily available worldwide, this engine has been in production since the 80's apparently, and still is.

-Reliable Japanese quality

-Smooth 3 Cylinder power delivery, will save the transmission and final drive.

-Cheaper than the alternative due to secondhand availability

-Multiple versions avaiable

Disadvantages:

-Size constraint, might not fit, will likely need to modify the lower frame parts.

-Little less power than alternative

-Water-cooled, will need radiator.

-No-one has fitted this engine into a Dnepr before.

(Backup) Kipor KM2V80

http://www.rotek.at/a000/002/000002287_00_RT_A_de.html

http://www.kiporpowersystem.eu/product/KD2V86F.htm

Advantages:

-Will fit in unmodified frame.

-V-twin power...

-Has been done before

Disadvantages:

-Parts not available on demand.

-Less fuel efficient

-Chinese quality

-Limited to no availability, might need to pull it out off a NEW generator.

-Water-cooled, will need radiator.

(2nd Backup) Kipor KD2V86

http://www.rotek.at/a000/002/000002287_00_RT_A_de.html

http://www.kiporpowersystem.eu/product/KD2V86F.htm

Advantages:

-Will fit in unmodified frame.

-Has been done before

-Air-cooled, no radiator, maybe oil cooler.

Disadvantages:

-Parts not available on demand.

-Less fuel efficient

-Chinese quality

-Limited to no availability, will need to order from abroad.

-Has less power than Kubota

Now the next step is actually purchasing, (beg, borrow, steal,) said components. Although I will need a way to obtain said budget...

In other news Jeroen, (Boutje on the forum), from VVMracing has agreed to help me out with the machining and welding bits!

And I've got a name for the bike, at least for the work in progress...

The Westenberg Special!

As always please share your tougths!

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

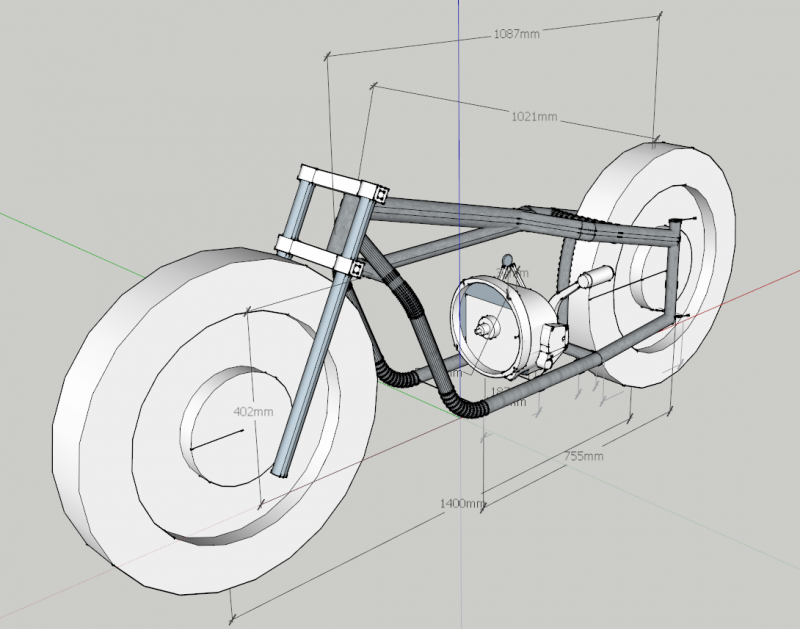

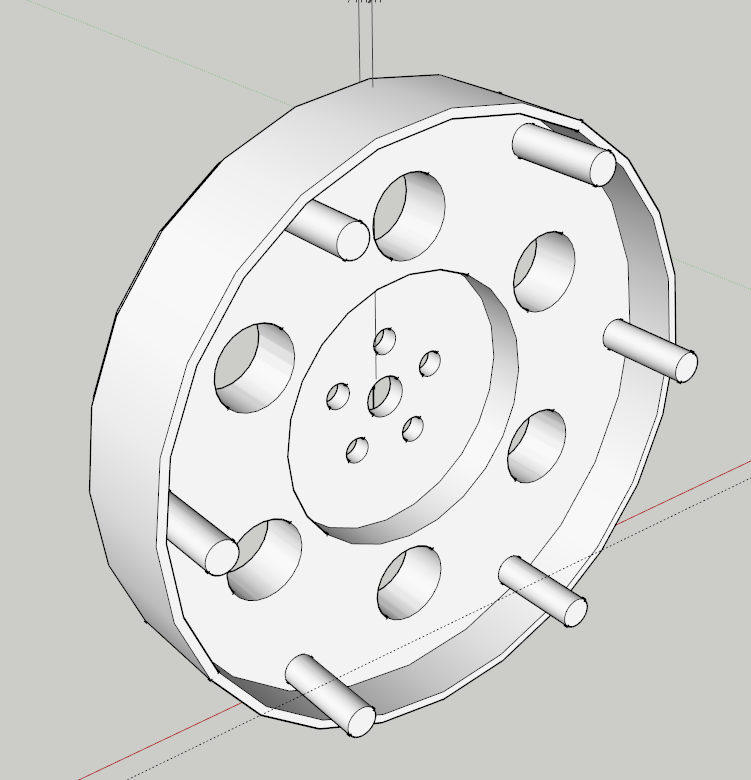

# 4 - 3D Models!

Date: 20-1-2015

Status: Designing second stage

Well then I thought it time for another update, I still have not moved to a new house but all in due time. In the mean while,

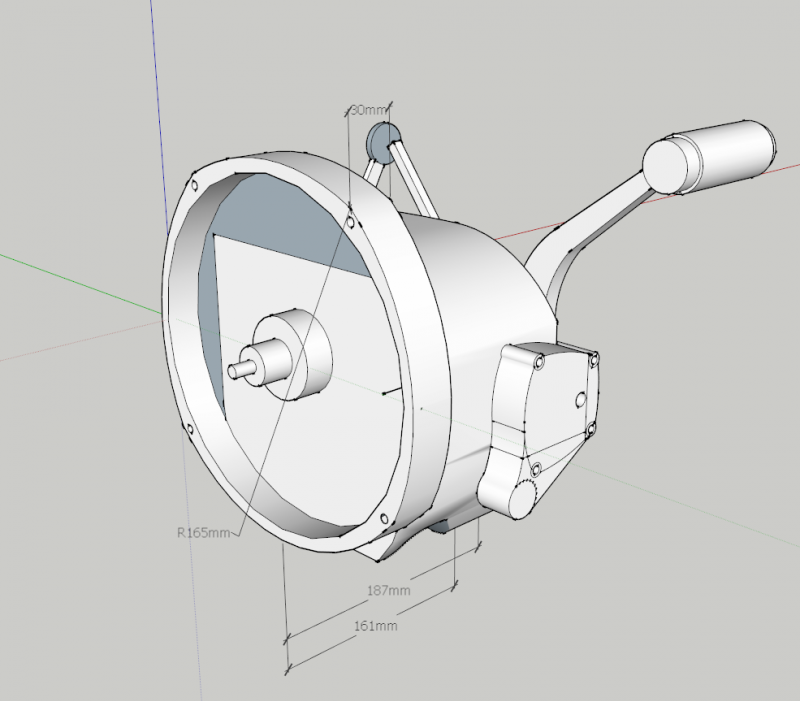

I've gone about making a 3D model of my yet-to-be diesel motorcycle to check if it'll all fit inside the frame and what I would need to change to make it fit...

Here are my results!

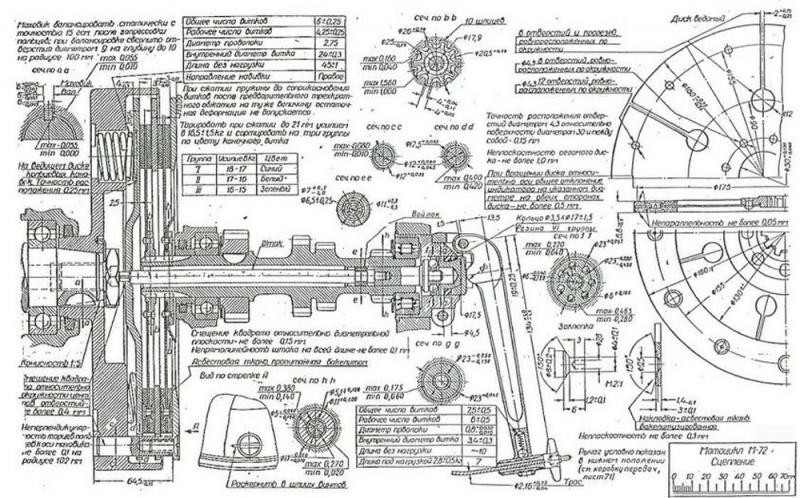

Technical Drawings

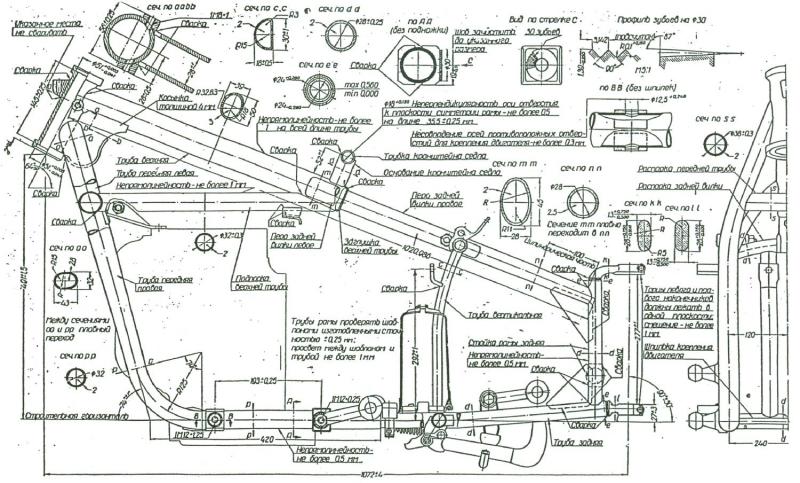

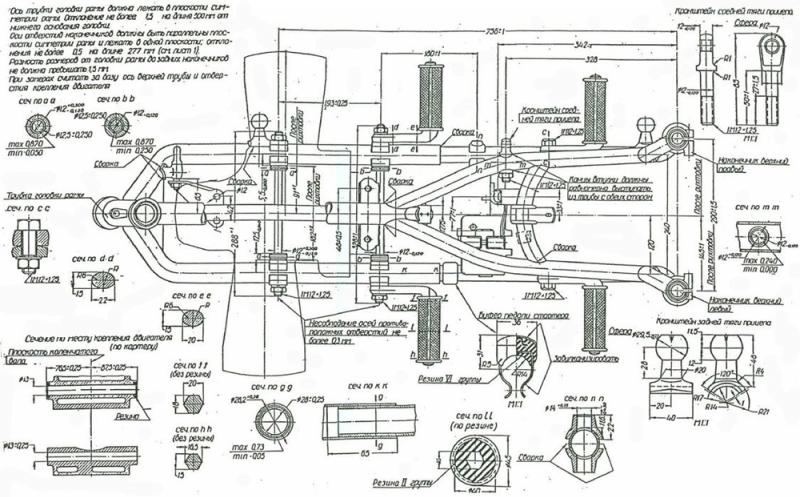

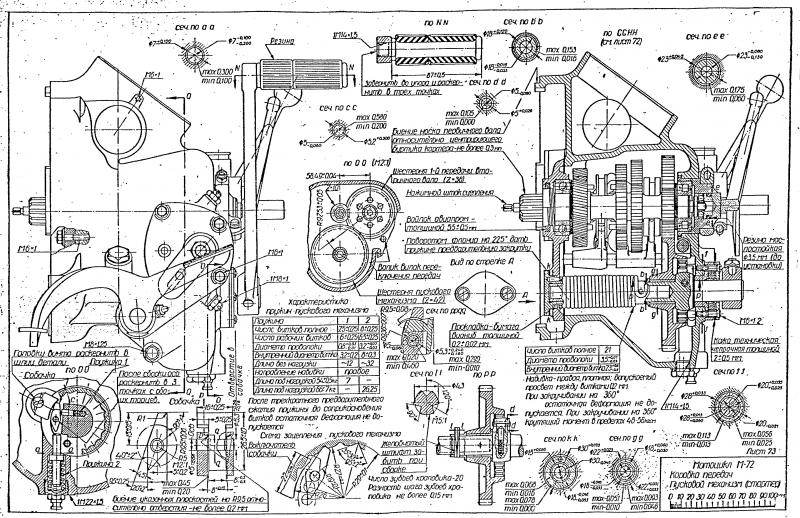

To make said detailed 3D models I'd need something to base them off, so I went on to search for technical drawings of the Dnepr K-750... I couldnt find any,

but I did find drawings for the Ural M-72 where the K-750 is based upon. Thus meaning that they are VERY similar in construction and dimension. So similar that

you can exchange engines and gearboxes. There's a catch tough... They're written in russian...

Examples!

What came out of that is this, keep in mind the wheels are the "worst" possible scenario of 4,00x19 and the front forks are a placeholder.

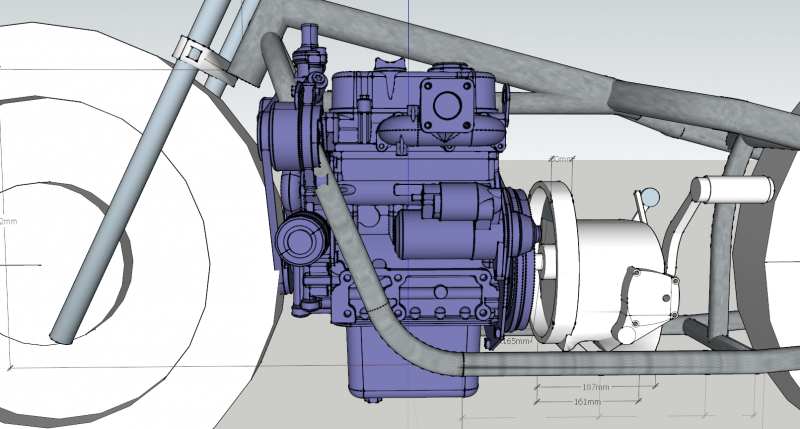

Now I needed to get some technical drawings off the engine I'd like to use... Couldn't find any online... So I paid a visit to the main supplier of Kubota in the Netherlands!

Much to my surprise, after I explained what I was treeing to do, I walked away with technical drawings AND a detailed 3D model off the D722...

Score! With compliments from Prins Maasdijk in the Netherlands http://www.prinsmaasdijk.nl/

Next up, rough gearbox model with proper placement in frame.

Design

So... Time to stick that mean diesel in there... Leave some place for a modified clutch assembly...

Good news, it clears the lower frame parts. Bad news, it's too long for an un-stretched frame and the valve cover clips the upper frame as I feared.

Stretchin' time!

Keeping in mind the limit of 50mm extra wheel base length I decided to move the front wheel 45mm forwards, hoping that it will give me enough space to make this work.

I had a couple of stabs at designing something but please share any ideas you might have. Also tell me which you find most viable in terms off contructability and strength.

First try: Kinky, Because it has a kink in the upper frame bit.

Second try: Lowrider, lowered engine, transmission, wheels. Don't know if this would work due to drive shaft clearance...

Third try: The Split, Split upperframe whats more to say?

So on to the next problem, flywheel and clutch. I'd like to keep the Kubota electric starter so that means that I will have to keep the starter gear ring on the flywheel.

Again I've had a couple of stabs at it, please give me your input.

Kubota flywheel, starter ring highlighted in red.

Kubota Front, those bolt holes are going to get in the way.

Kubota Rear, those balancing holes, they looks to big to just be balancing the flywheel. Do they balance the engine aswell? Also they get in the way

Ural M-72 Flywheel

My attempts:

First try, machined from Kubota flywheel. Holes drilled for springs and clutch "pegs" welded to front. Realized clutch "pegs" whould hit the starter housing and holes would reach the balancing holes on the back.

Second try, machined from Ural flywheel. Starter ring removed from kubota flywheel and rewelded to Ural flywheel. Actually the first time I encountered the starter clearance issue.

Third try, machined from kubota flywheel. Turned off too remove pesky bolt holes, holes drilled for springs and clutch "pegs" welded to front then again turned off too clear starter housing.

Fourth try, double whammy, total overkill. Machined from both flywheels. Kubota flywheel turned down to remove bolt holes, removed as much weigth as possible from Ural flywheel then welded to Kubota flywheel.

Hope its clear to you all and I didn't forget something but don't fret to ask anything, I'll make some more screenshots if needed.

As is customary now, please share your thougths.

Massive post is MASSIVE.

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 5 - Moving along!

Date: 9-4-2015

Status: Intermission

Right, almost one year since my first post about this build but things have been happening all tough not directly connected to the dieselbike.

First off all I am moving to a new house, which means I'll finally have the space to build the darned thing!

This does mean my project has been on hold for a bit now, hopefully I'll be able to continue as soon as I move into the new house and things settle down.

Secondly, I've got my main funds goal completed so I'm green on that front as well!...

...Provided I do not get any really big unexpected costs...

...Which might be a thing as this is still a custom motorcycle...

...Anyway!...

In terms of actual design, Boutje suggested using a car clutchpack to fix the starter ring problems along with a custom flywheel.

He said, that he can machine the original "imbalance" into the new custom flywheel and also move the starter ring over.

This will also make the entire thing way more compact.

Hopefully I'll be able to go to the Big Knock this year as that will likely cut into the funds I reserved for the dieselbike, but it

might simply be worth it to see what problems and solutions you guys encountered and came up with.

That's all for now, making up for the righteously massive post of last time I guess. More to come, (hopefully not too much), later!

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 6 - Back on track.

Date: 19-6-2015

Status: Obtaining parts

Checking in with good news!

I have moved into my new house and...

I'VE GOT MY SHED!

DER SHED.

Took me long enough to build the darned thing... (Tip: Don't buy sheds manufactured in the UAE...

Anyway, back on track!...

I've got the space, budget, and plans to build my bike.

Now I need the parts, primarily a Dnepr K750 donor bike and a Kubota D722 engine.

My visit to the Big Knock this year has yielded plenty of information including an issue with Dnepr brake drums... ...Which is fixable I think. I'll let you guys know more once I start working on that.

Firstly I'll build the bike and hopefully in time for the next Hamm rally, a long shot I know but you might just see me there on a rough version of my bike!

That's all for now really, not a lot but once again please let me know what you think.

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 7 - Engine!

Date: 6-7-2015

Status: Obtaining parts

I've bought an Kubota D722!

But it doesn't want to turn over.

Starter does this:

https://youtu.be/v4wU742dwl4s

First I thought I had it the polarity the wrong way around but it does the same thing either way.

So either the starter ist kaputt or the battery doesn't have enough juice left in it. (Measured 12v, leaving it charging overnight, try again tomorrow)

Engine isn't seized because I can actually grab the lower pulley and turn it around trough its compression by hand, so the starter should have no problems with this.

Anyone offer advice on the matter?

Edit; Obligatory https://youtu.be/v3y7CvHxF54?t=4m12s

Engine! #2

Date: 7-7-2015

Well then, I've gotten the starter engine to work!

Seems the bendix was stuck... ...What a rubber mallet can't fix in this world...

But now I cant seem to get the air out of the system, so... Anyone have a clue on what I'm doing wrong here?

https://youtu.be/bKKuqeQ_zeE

I did get diesel to the flywheel side injector after recording this. But it wasn't much.

Engine! #3

Date: 8-7-2015

Well then, still no luck. Plenty of fuel coming out of the return line but nothing out of the pump.

https://youtu.be/lxhmXF2FTqE

Engine! #4

Date: 8-7-2015

Right, I havn't got the faintest as whats causing this. I've pulled the injector pump guts out and cleaned them. I even checked if the plungers would come up and down while everything was disassembled and they did.

So I put everything back together and tried to bleed the air out of the lines again... Here's the result:

https://youtu.be/0j1iHy1R7ys

Engine! #5

Date: 9-7-2015

Well then, I smell of eau de diesel but I've gotten the waterpump side injector to work VERY briefly.

What I'm thinking is happening is that the plungers are getting stuck once they reach the top of their stroke in the plunger barrel.

I have been pushing them back with an allen key and that seemed to have freed up one of them for a while but it got stuck again.

So anyone have a more permanent solution for this?

Also if I remove the assembly will I ruin the timing on my engine? I'm not really sure but I think it should be fine as they are inline and their being driven by a camshaft which is connected to a gear drive...

And with assembly I mean one of the 3 injection pumps, not the entire injector pump block.

Engine! #6

Date: 10-7-2015

Well then I gave it one more shot.

Checked the glow plugs for continuity again, check out fine, almost no resistance.

Cylinders were filled with WD-40 the day before, so plenty of starting fluid I would think.

Glowplug hooked up and waited about 10 seconds before starting.

Result;

https://youtu.be/EdONOSyID4Q

Disappointment.

Engine! #7

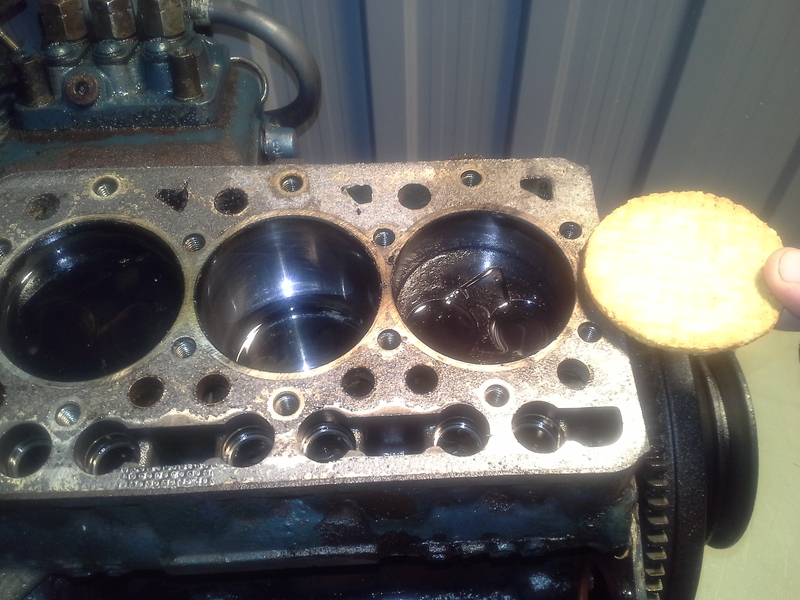

Date: 12-7-2015

As I do not have any real way of pulling the valves out and putting them back in, I had to get creative to take a look at them.

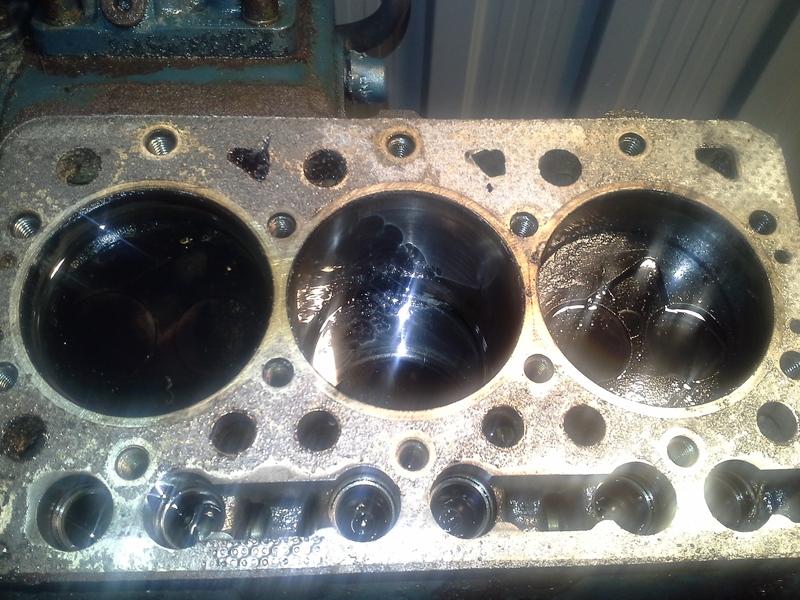

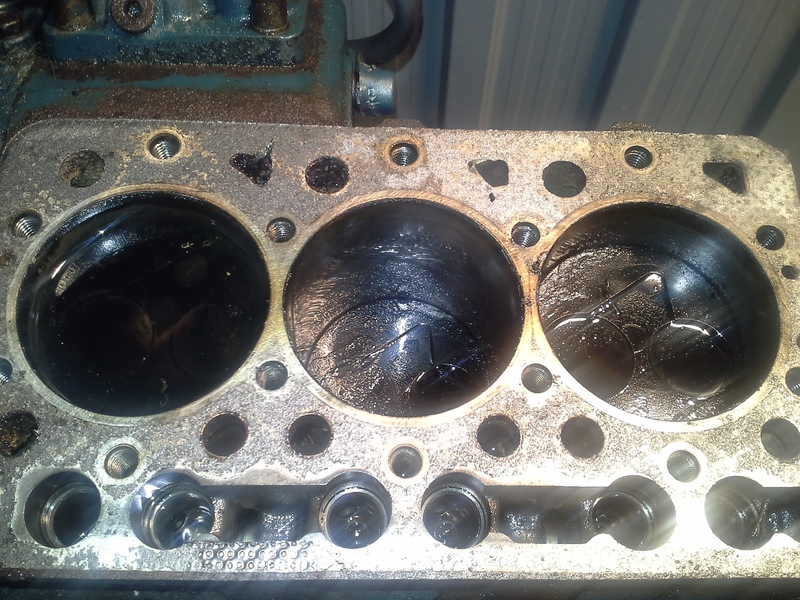

To my untrained eye, they look fine. What do you guys think?

Engine! #8

Date: 12-7-2015

Well I gave it a shot, here's the results. Couldn't do the valves as I cannot lay them down flat enough.

Begin

~25min

~35min

~40min

~45min biscuit for scale.

~60min

The flywheelside is pretty much empty and the middle one is about to go as-well. Water pump side is fine.

Now there is a 500w halogen lamp shining on top of it... I'll check again in about an hour.

Engine! #9

Date: 12-7-2015

Right, last picture of the "seep trough test".

Middle and flywheel side are gone it looks like.

Gasket area seems ok.

So, pulling the pistons out...

That means pulling the oil pan off... No problem I thought...

THESE...

F#$%&ING...

BOLTS!!!

RAGE.

Ok, which geniuses decided to use 12 pointed bolts?...

I cant pull the piston out untill I get one of those socket heads.

Meanwhile, this normal?

https://youtu.be/_cZGh7wJjcA

Engine! #10

Date: 14-7-2015

Tried to pull the crank shaft out, of course the pulley bolt is stuck, and I mean STUCK.

Went at it with pneumatic wrench at 10 bar, still wouldn't go. I even tried an cross tire iron with an 2 meter long pole on it for more torque.

https://youtu.be/i5hnybLL1E0

Idea's to get the bastard off? I've already soaked it in penetrating oil and WD-40.

Here's a clip and some pictures off the pistons and Cylinders, they seem to look fine. Tougths?

https://youtu.be/pG4krt5XENI

From waterpump to flywheel.

Cylinder 1

Cylinder 2

Cylinder 3

Engine! #11

Date: 14-7-2015

I got her loose...

https://www.youtube.com/watch?v=b4d-nuE ... e=youtu.be

All tough it took about a gallon of penetrating oil, a whole lot of propane and a 2 meter long steel pole, which is now bent, with me hanging off of it.

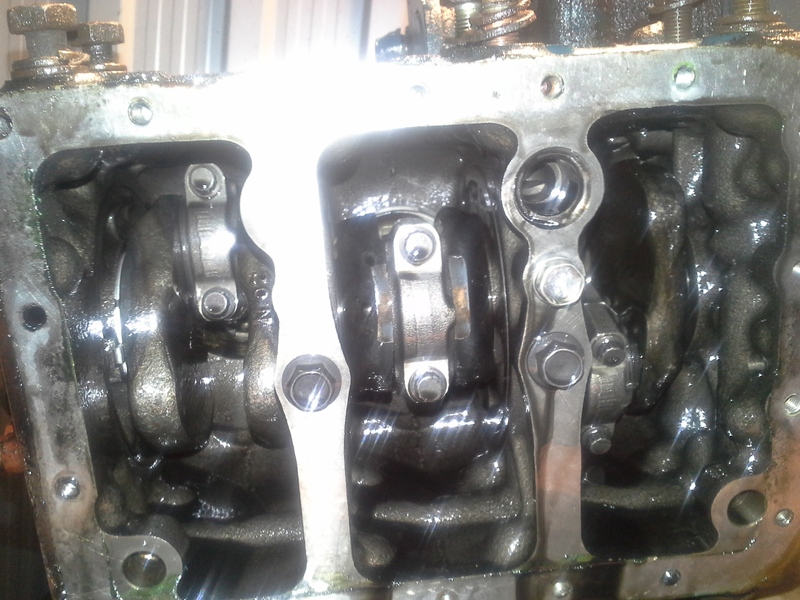

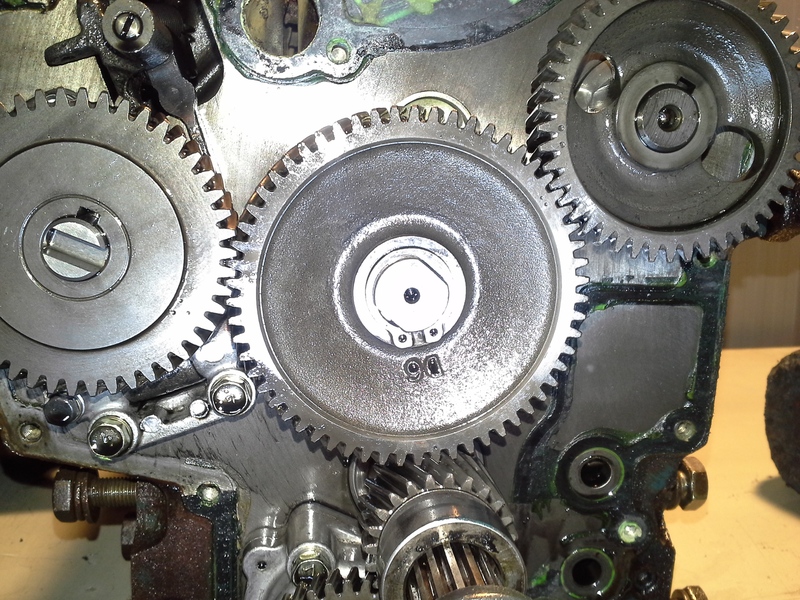

Once I got the cover off some things caught my attention.

The timing marks are off and however much I turned the gears they would not align. So 'dere's yer problem.

Once I was done completely disassembling the engine.

I figured I might pay some extra attention to the Injector pumps, it appears this pin is stuck. (It's called the rack pin right?)

So tomorrow I'm heading over somewhere to measure out the engine and see if it's salvageable.

Engine! #12

Date: 15-7-2015

Results are in, engine is in prime condition except for the piston rings which were totally worn out!

So now I just have to replace those rings and refurbish the injector pump and injectors.

If all goes according to plan I'll have a working engine in about 2 weeks!

Glad to be of help! Don't let an diesel engine sit for too long tough, it'll kill your pumps...mark_in_manchester wrote:Just a word of encouragement from me, and thanks! I have a mystery Daihatsu engine which has been sitting around for a year with no compression, while my bike languishes with (at best) a blown head gasket. Your thread is encouraging me to have a go at the spare engine at long last!

Engine! #13

Date: 19-7-2015

Engine is still in bits but I'm on the hunt for piston rings and a gasket set.

I have also left the whole injector assembly along with the pumps at a refurbisher to fix it up.

Once the gaskets and rings are here I will start reassembly.

Other things that need to be done on the engine are porting the head to get more power out of it and modify that darned oil pan.

Engine! #14

Date: 4-8-2015

Engine is back together!

All-tough It wont run until it´s in the bike due to the fact that I need too calculate proper airbox/filter size and build it. The same goes for the exhaust.

If anyone has advice on the matter, I'm still treeing to figure out the whole Helmholtz resonator thing, I get the theory but the calculations eludes me.

I've also been on the hunt for a donor motorcycle and managed to get a gearbox in advance so I could start adapter plate and clutch construction.

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 8 - DonorCycle!

Date: 7-8-2015

Status: Obtaining parts

Look what arrived in the mail today!

https://youtu.be/KrS60n1PWaU

Smokes like hell (black) from the right-side cylinder and runs really hot while the other is cold and its carb is leaking fuel everywhere!

Sadly enough I need this engine to work for another 500 KM because I need to import it into the Netherlands on paper and get a plate for it... ...and that means riding it to the test center...

I'm guessing the right side is over-fueling like mad and the left is starving or just isn't running, thoughts?

Had a blast tough!

# 8 - DonorCycle! #2

Date: 21-8-2015

Status: Building/Obtaining parts

Quite an event-full week has come and gone but the DonorCycle has passed inspections as an petrol powered bike and is now legal in the Netherlands!...

...So lets tear it apart!

Which took about 3 hours, taking it easy.

Ready for a diesel transplant I'd say, and then off to get inspected again!

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

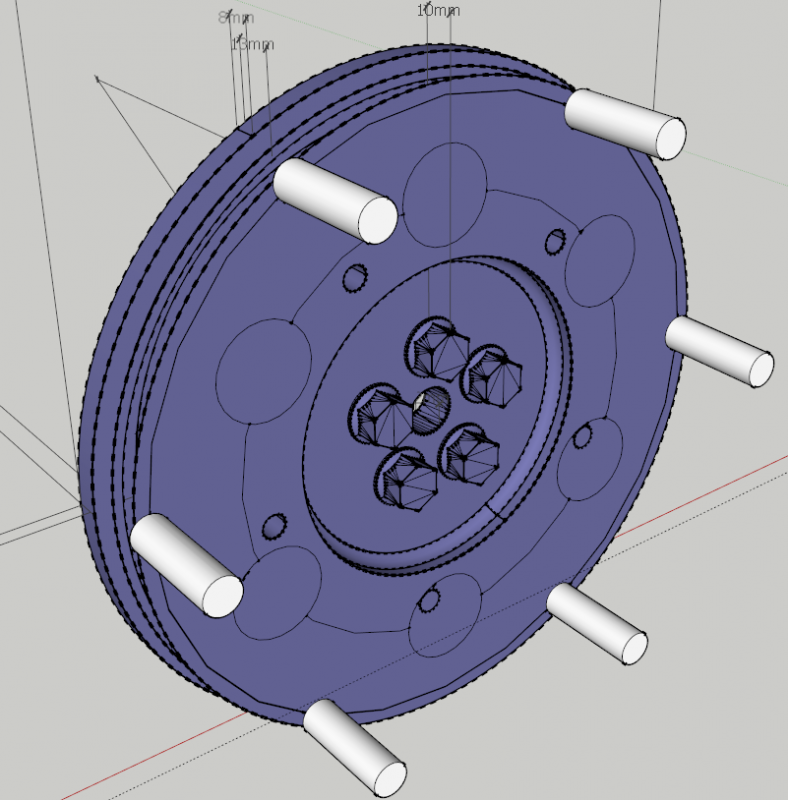

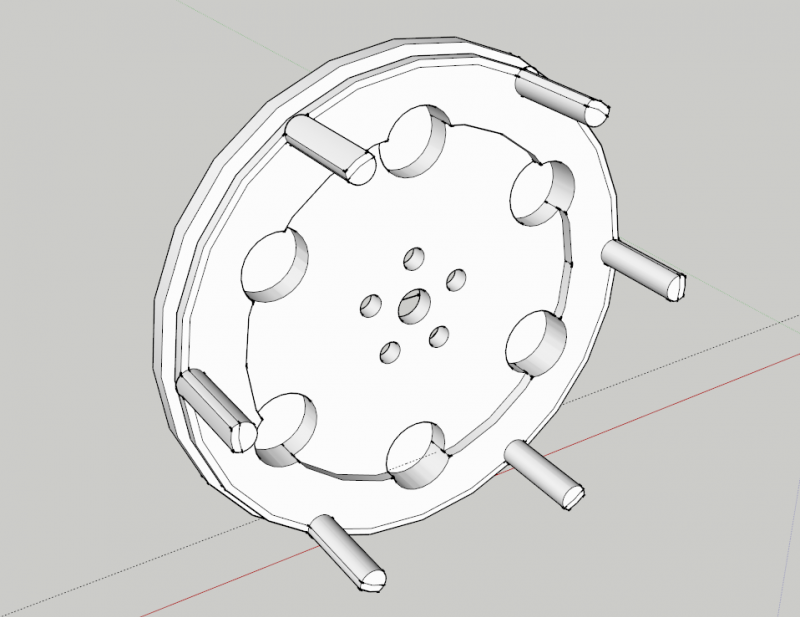

# 9 - The Build.

Date: 5-10-2015

Status: Building

As the title suggest, the build is finally underway!...

...And I've got a minor technical miracle to show off.

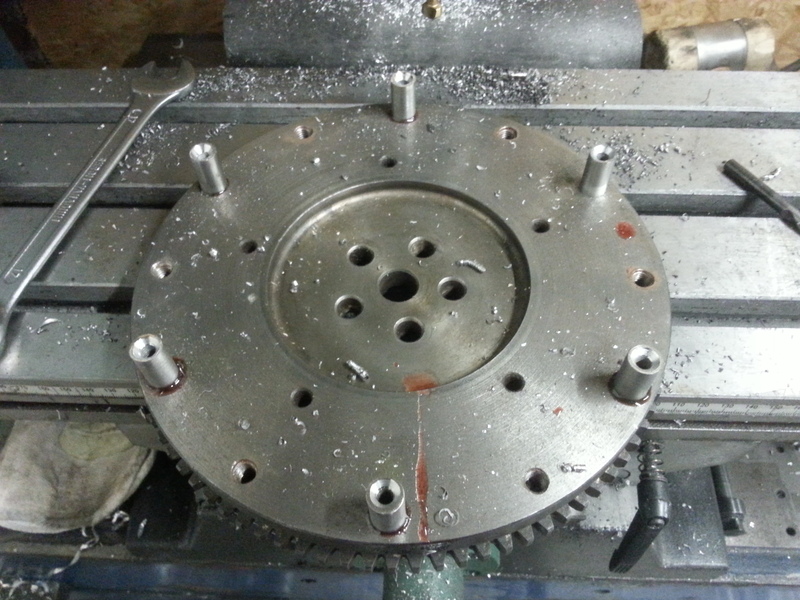

Behold!...

A kubota flywheel modified to fit a Dnepr K750 clutch pack!

A project which sounds simple... ...but was more trouble than I ever imagined.

For starters, the pegs that hold the clutch together on a Dnepr have an alignment that made me think that some guy with a hand drill just free handed them in...

So, forget just having evenly spaced out pegs, because those wont fit the center metal clutch plate, that means it will only ever go on in ONE way.

Nevertheless, it has been made...

On to the springs then! Shame about the balancing holes on the back of Kubota Flywheel tough!

The stock spring holes whould end up merging with the balancing holes on the backside of the flywheel.

So to solve that problem we used 2 kinds of different sized springs and spaced them out in an 3 on the inside and 3 on the outside pattern.

Added bonus; much, MUCH stiffer springs...

So now just make an clutch alignment tool, because why order something when you can just create it in 10 minutes...

...Aaaand now the last clutchplate is hitting the bolts which are holding on the flywheel, couldn't even assemble the clutch.

What now!? Why counter sink the bolts of course!... ...Just gotta make those M10 holes in the crankshaft to accept M12...

Ain't it pretty?

And now the result... ...technical porn!

Next on the list: Making an adapter plate!

Meanwhile I got some parts!

All the gaskets and seals I'll need,

2 Clutch plates of a newer design which didn't fit,

A tachometer,

20/26 third gear,

23/23 fourth,

and a 10/35 Final Drive.

The gearing will mean that my shifting speeds look like this;

On a side note, who said you can't fit an motorcycle into the back of an family car?...

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 10 - The Build.

Date: 21-11-2015

Status: Building

Project had a temporary hold up due to various things but some progress has been made.

A picture is worth a thousand words, I've got six.

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

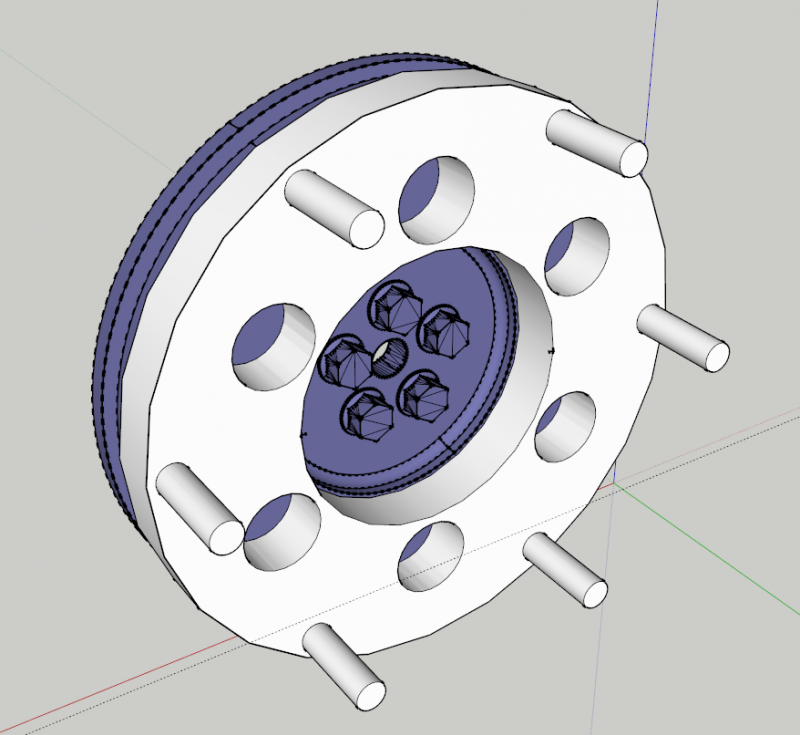

# 11 - The Build.

Date: 25-2-2016

Status: Building

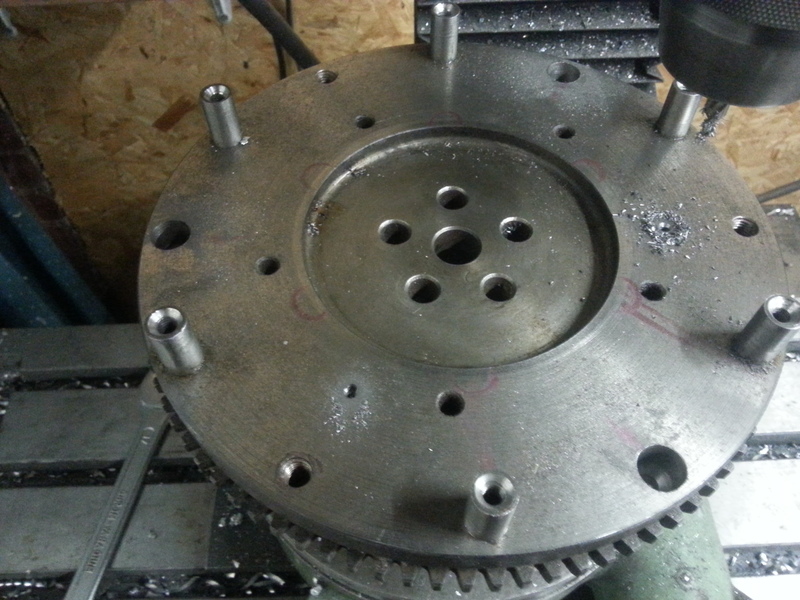

Another 2 months have passed and the plan of reusing part of the Dnepr engine casing as an adapter didn't work, sadly enough. So one had to be created from scratch.

New plan; Aligning gearbox/clutchpack with engine crankshaft/flywheel by machining the 4 "posts" to make it all fit together properly before welding it all up.

The general idea.

Checking runout; all within 0,1 mm.

https://youtu.be/4snJvHV9miA

...And welding it up, you can still see the spacer in between.

Coverplates.

Would be a shame if the starter didn't fit.

Result!

So... Something about choppers, am I rite?

Now lets see if my measurements and 3D modelling was right about fitment!...

On, the, money.

All-tough, as feared the valve cover is fouling the upper frame and the fuel-tank bracket plus there's a bit of an clearance issue with the water-pump pulley.

That's all for now but its actually starting to look like something!

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 12 - The Build.

Date: 19-6-2016

Status: Building

Man, this endeavor is taking a while. But time is money and I do not have a lot of money, so, time it is.

Taking part in two motorcycle accidents doesn't help either.

Main frame and engine mounting bits are done!

But of course the belt now fouls the frame thus there was a need to get creative.

It's all so close now, hopefully more soon!

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 13 - The Build.

Date: 21-8-2016

Status: Building

Owning an diesel bike also means that there's a need for a vessel to contain said diesel on the vehicle... ...19 Liters of the stuff.

Behold!

With fuel return line!

As you have probably seen, there's some rust in the tank, I figured i'd remove it with some diluted Rustyco... Yeah, bad idea, don't do it. That needed re-welding.

'

'And of course the brilliant Monza fuelcap, here's some pictures.

Now for anyone else wanting to do this, a word of warning. The Dnepr fuel tank is made from highcarbon steel which made it very hard to weld, it might just be easier to make a new fuel tank.

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 14 - The Build.

Date: 13-11-2016

Status: Building

Well then, all-most 3 months have passed but this time, stuff got done! So much in-fact that I didn't even took the time to post it all.

So here comes the catch up!

One of the first things a friend of mine noticed when I got the Dnepr was the fact that the rear springs were set slightly forward, which is an absolute no-no for suspension as this will cause the opposite of progressive springs.

So that had to be fixed, and while I was at it I might as well get some actual proper springs for the thing.

Upon disassembly we also noticed that the swing-arm mounting method was also absolute rubbish. Another thing to be fixed!

Insert, proper bearings! Courtesy of an Yamaha XJ750.

With that fixed, onto the shocks! YSS Progressive shocks, mounted canted forwards for added progressiveness. Isn't it a thing of beauty?

Now an engine needs an exhaust, and wouldn't it be nice if it was tuned in such a way that the exhaust pulses will pull even more air out of the combustion chamber?

First off, flanges, stainless CNC-milled, flanges of-course...

https://youtu.be/GVtR3P48zCI

Perfect fit! Time for the tiniest exhaust bends ever!

Those were fun to make... Now an collector!

Put it all together...

Add some more bits in-between...

Close the gaps, and if you're wondering. Yes, the runners are of different length but, because of the design, the center exhaust pulses carry more momentum thus nullifieng the difference in length.

Now to add some length and direct the exhaust where I want it to go.

I guess I should add a muffler... But of-course an resonance muffler, non of those power-robbing baffles in here!

Now for the finishing touch! Cleaning up the oxidation off of the welds.

Exhausting, wasn't it? But we're not done yet!

More clearance issues to resolve...

And having had enough of searching for an suitable thermostat housing top, its a long-un!

Peek-a-bo.

Slightly cheating... ...And a bit more welding, seems an zinc-primer really helps with welding these tanks, somehow.

Oil-pan mods! I wanted an temperature sensor and properly located drain plug.

And I'll leave you with an slight preview on what to expect next time...

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 15 - The Build.

Date: 16-1-2017

Status: Building

Another year, but this time I'm going to finish the darned bike...

As promised, I give you!...

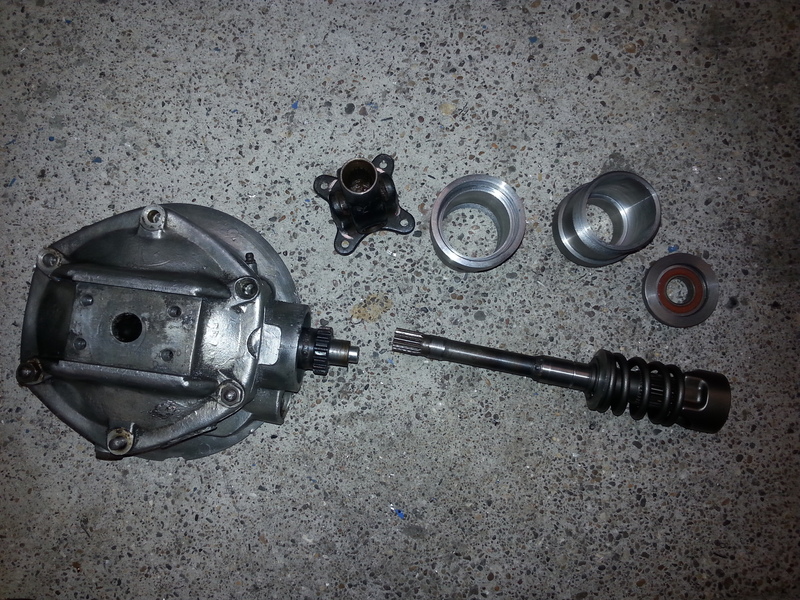

...THE FINAL DRIVE!...

Including!...

Transmission damper...

..and an properly located universal joint!

Slightly modified pinion gear...

Good bye exploding hockey pucks! It might be an tight fit tough...

Also, something about diesels having a lot of...

...TORQUE...

That'll be it for now. Next up, partial assembly!

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====

# 16 - The Build.

Date: 23-4-2017

Status: Building

Well, I did partially assemble it, but I forgot to take pictures. And due to stuff I haven't been able to make as much progress as I liked to, but some has been made.

To start the list: I purchased some Radiators, figured it be best for front wheel clearance to mount them on the sides.

Next up: I worked out clearances for an special intake manifold to match the exhaust.

One needs a place to sit, but not any old seat will do for my bike.

This thing is gonna be really heavy, those old drum brake were always going to an issue... ...time to address that.

Put the first coat of paint onto the engine as it was starting to rust, might change the colour.

And last but not least, I've ordered an new spline hub as my old one was worn out.

Of course this needed precision fit bolts due to this being the most stressed part of the bike. Ready for aligning and wear in with some lapping compound.

I've also disassembled the gearbox for refurbishing and changing of ratio's, more on this later.

That's all I can think of at the moment, more to come!

===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== ===== =====